ボルトとナットの締結と開放は、非標準的な設計を採用し、一致する。

非標準の工具は、開口部と締結部の問題を解決するために使用される。一般的に、他の

レンチを挿入することはできません。ナットとボルトの外観デザインでは、非標準のスロット、

開口または五角形、七角形、九角形または特注の対応溝工具

盗難防止効果が非常に高い

冷間圧造加工は、切削の少ない、あるいは切削を必要としない新しい圧造加工のひとつである。

金属。の作用による金属の塑性変形を利用した加工法である。

外力を受け、金型の助けを借りて、金属の体積を再分配し、移動させる。

必要な部品やブランクを製造します。冷間圧造工程は、標準的な

ボルト、ネジ、ナット、リベット、ピンなどの留め具。

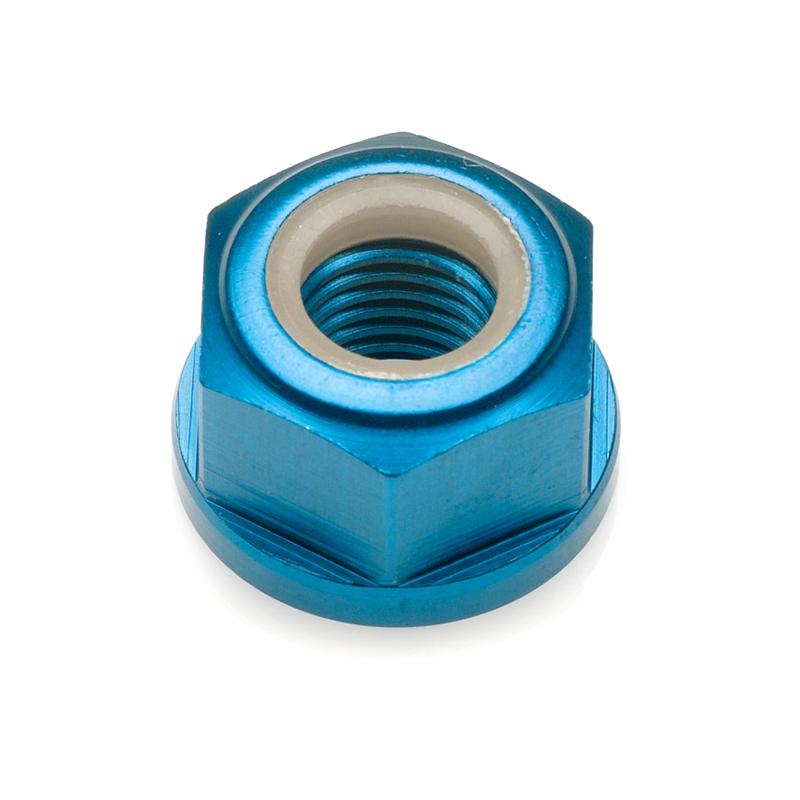

ブルーオキサイド付きアルミニウム・ナット コーティング

アルミニウム製ナット ブルーオキサイドコーティング は、軽量化と美観が重要視される用途向けに設計された、軽量で耐食性に優れたファスナーです。ブルーオキサイド仕上げは、ナットの導電性と非磁性特性を維持しながら、装飾的で穏やかな保護層を提供します。

主な特徴

-

素材:

-

素材 アルミニウム合金 (通常は6061-T6または7075-T6)。

-

軽量(鋼鉄の1/3)で耐食性に優れる。

-

-

ブルーオキサイド・コーティング:

-

A 化成皮膜 (アルマイト処理ではない)を提供する:

-

軽度の耐食性 (アルマイト処理よりは劣るが、むき出しのアルミニウムよりは良い)。

-

装飾的なブルーブラック仕上げ (美観や色分けを目的として)。

-

非導電性干渉 (導電性に影響を及ぼす可能性のあるアルマイト処理とは異なる)。

-

-

アルマイト処理よりも薄いため、ネジの寸法を大きく変えることはない。

-

-

ロック機構(該当する場合):

-

ブルーオキサイド・アルミ・ナットには、以下のようなものがある:

-

ナイロンインサート(Nyloc) 耐振動用。

-

鋸歯状フランジ より良いグリップのために。

-

プレベリングトルク設計 (オールメタルロック)。

-

-

-

利点がある:

-

軽量 - 航空宇宙、自動車、サイクリング用途に最適。

-

非磁性・導電性 - エレクトロニクスおよびRF用途に使用される。

-

美的アピール - カスタムメイド、オートバイ、ドローンなどによく使用される。

-

中程度の耐食性 - 屋内または軽度の屋外使用に適している。

-

-

制限:

-

アルマイトやステンレス鋼のナットに比べると耐食性は劣る。

-

スチールやチタンに比べて強度が低い。

-

ブルーオキサイドは、摩擦によって時間の経過とともに摩耗する可能性がある。

-

一般的な用途:

-

航空宇宙&ドローン (重量に敏感なアセンブリ)。

-

自動車とオートバイのカスタム (装飾ファスナー)。

-

電子・電気エンクロージャー (非磁性、導電性)。

-

自転車&スポーツ用品 (軽量部品)。

結論

ブルーオキサイド・アルミ・ナットは、適度な耐食性と魅力的な仕上げが望まれる、軽量で非磁性用途に適した選択肢です。しかし、より過酷な環境には 陽極酸化またはステンレス鋼ナット の方が適しているかもしれない。

レビュー

レビューはまだありません。