冷間圧造加工は、切削の少ない、あるいは切削を必要としない新しい圧造加工のひとつである。

金属。の作用による金属の塑性変形を利用した加工法である。

外力を受け、金型の助けを借りて、金属の体積を再分配し、移動させる。

必要な部品やブランクを製造します。冷間圧造工程は、標準的な

ボルト、ネジ、ナット、リベット、ピンなどの留め具。

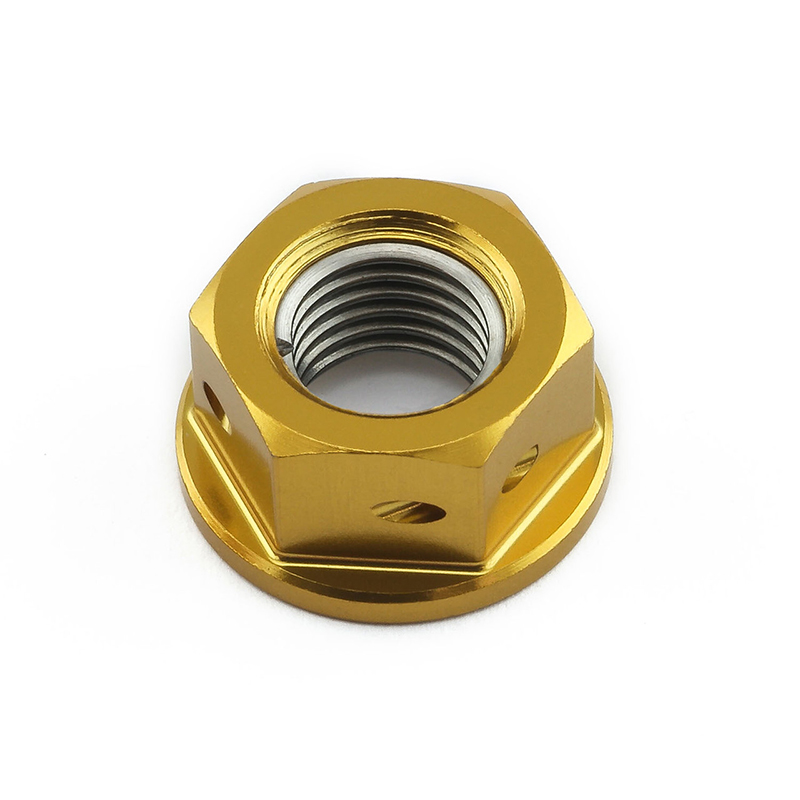

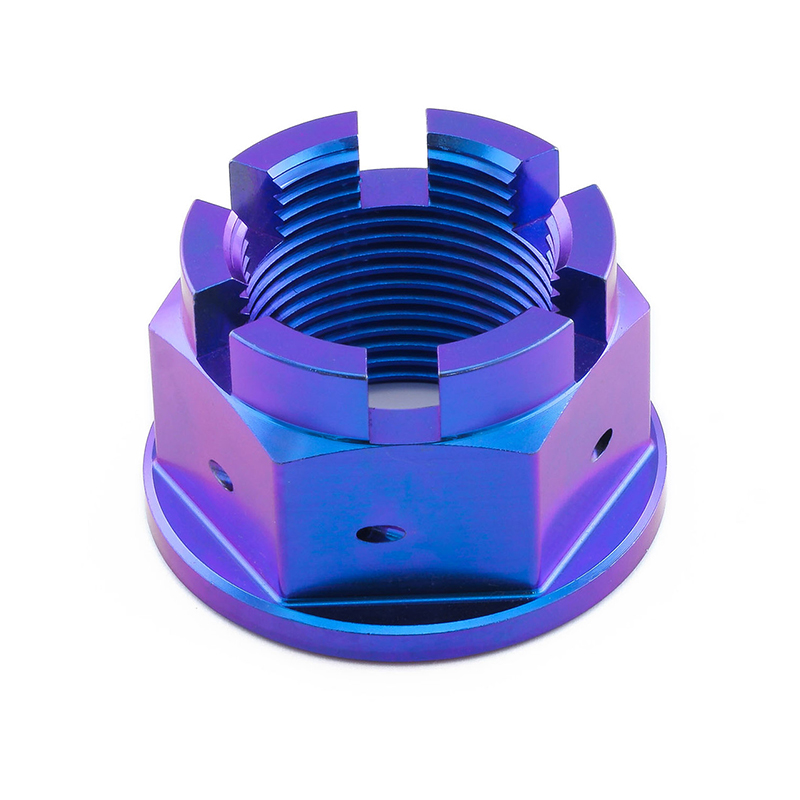

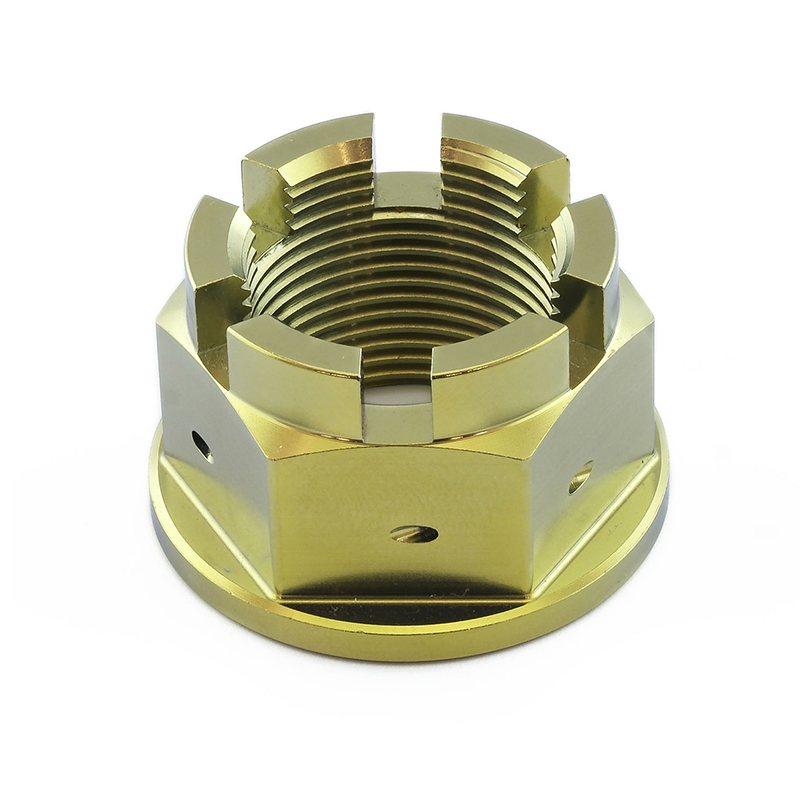

A 安全ワイヤーナット 酸化アルミニウム・ブラック は、特に高温または過酷な環境での確実な電気接続のために設計されたワイヤーコネクターの一種です。ここでは、その主な特徴について詳しく説明する:

1.素材と構造

-

酸化アルミニウム(Al₂O₃)コーティング:ワイヤーナットは、高い熱安定性、電気絶縁性、耐食性で知られるセラミック素材、酸化アルミニウムでコーティングされている。

-

ベースメタル:通常、耐熱アルミニウムまたはその他の耐久性のある金属コアで作られ、構造的完全性を確保する。

2.色と識別

-

ブラック・フィニッシュ:黒色は、その特殊な用途を識別するのに役立ち、多くの場合、高温または工業用グレードの用途を示す。

- 酸化アルミニウム・ブラック

3.安全機能

-

耐熱性:酸化アルミニウムにより、ワイヤーナットは極端な温度にも耐えることができ、工業、自動車、航空宇宙用途に適している。

-

難燃性:燃えたり溶けたりしにくく、電気系統の安全性を高める。

-

安全なグリップ:振動や熱サイクルによるワイヤーの緩みを防止するため、内部ねじ切りまたはスプリング機構により、ワイヤーがしっかりと接続された状態を保つように設計されています。

4.アプリケーション

-

標準的なプラスチック製ワイヤーナットが故障するような環境で使用される:

-

高温電気システム

-

自動車用配線(エンジンや排気システムの近くなど)

-

産業機械

-

航空宇宙および軍事用途

-

標準的なワイヤーナットよりこれを選ぶ理由

-

優れた耐熱性と耐薬品性

-

振動の多い場所での機械的強度を強化。

-

過酷な条件下でも長寿命。

- 酸化アルミニウム・ブラック

特定の用途(自動車用、工業用など)に必要な場合は、サイズと定格がワイヤーゲージと温度要件に適合していることをご確認ください。詳細が必要な場合はお知らせください!

レビュー

レビューはまだありません。