冷間圧造加工は、切削の少ない、あるいは切削を必要としない新しい圧造加工のひとつである。

金属。の作用による金属の塑性変形を利用した加工法である。

外力を受け、金型の助けを借りて、金属の体積を再分配し、移動させる。

必要な部品やブランクを製造します。冷間圧造工程は、標準的な

ボルト、ネジ、ナット、リベット、ピンなどの留め具。

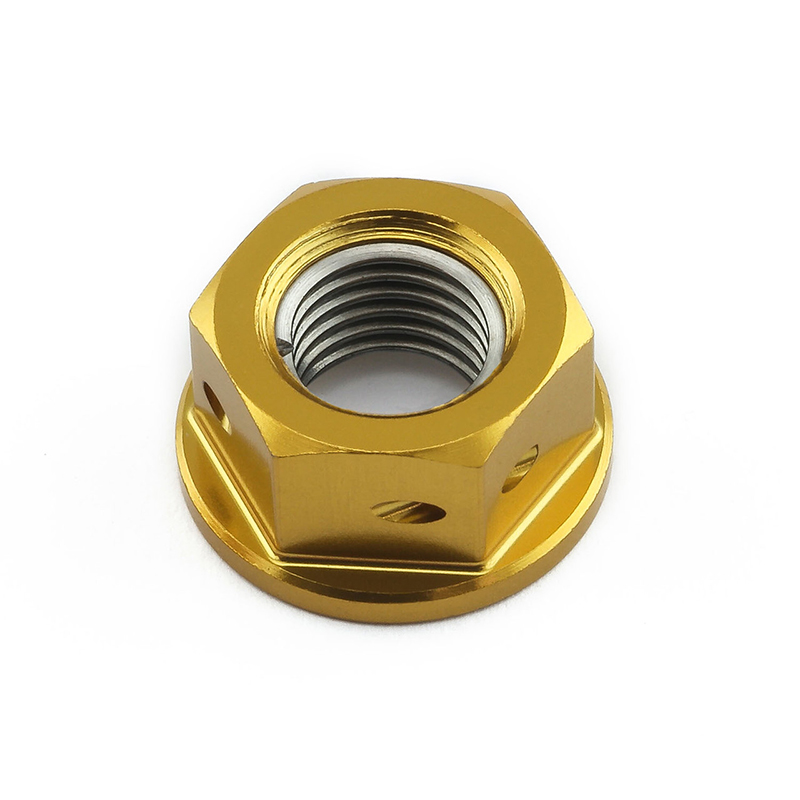

A 安全ワイヤーナット 酸化アルミニウム・イエロー は、特に高温または過酷な環境において、確実で信頼性の高い電気接続を実現するために設計された特殊なタイプのワイヤーコネクターです。ここでは、その主な特徴について全体的に説明する:

1.素材と構成

-

ボディ素材: 通常、高級素材を使用している。 熱硬化性プラスチック または 難燃ナイロン 耐久性のために。

-

内部コーティング/インサート: 内容 酸化アルミニウムで知られるセラミック化合物である。 高耐熱性 および電気絶縁特性。

-

色: イエロー (特定のサイズや温度定格を示すことが多い)。

2.主な特徴

-

高温耐性: について 酸化アルミニウム コンポーネントにより、ワイヤーナットは極度の熱に耐えることができ、工業、自動車、航空宇宙用途に適している。

-

セキュアな接続: 特徴 ばね付き金属コイル (通常は銅製またはスチール製)で、振動に強い強固な接続を保証する。

-

難燃性: シェル素材は燃焼や溶融に強く、電気システムの安全性を高める。

-

耐食性: 酸化アルミニウムは酸化や化学的劣化から保護する。

- 酸化アルミニウム・イエロー

3.アプリケーション

-

で使用される。 高温環境 (炉、エンジン、産業機械など)。

-

こんな人に向いている 自動車配線、航空宇宙、船舶用途 耐振動性が重要な場所。

-

こんな方に最適 アルミ-銅線接続 (そのような使用を想定している場合)。

4.安全基準と認証

-

遵守すること UL(アンダーライターズ・ラボラトリーズ)、CSA、またはIEC 電気安全基準。

-

特定用途向け 電圧(600Vなど)と温度範囲 (例えば、-40℃から+150℃以上)。

- 酸化アルミニウム・イエロー

6.標準的なワイヤーナットを超える利点

-

スーペリア 放熱 酸化アルミニウムによるものである。

-

強化された 機械的強度 振動の多い環境では

レビュー

レビューはまだありません。