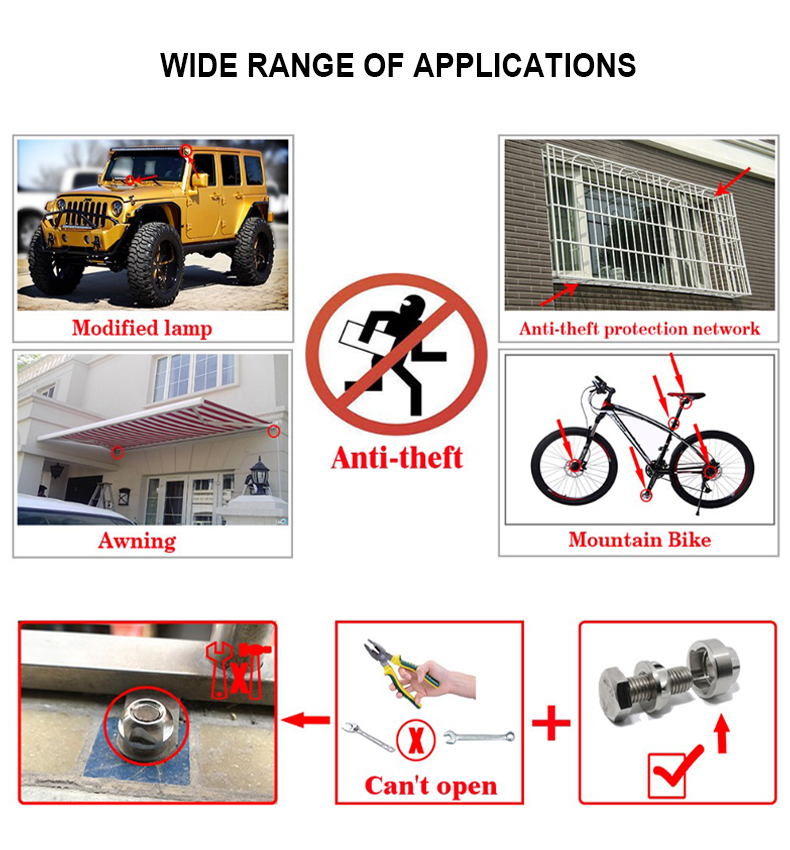

ボルトとナットの締結と開放は、非標準的な設計を採用し、一致する。

非標準の工具は、開口部と締結部の問題を解決するために使用される。一般的に、他の

レンチが挿入できない。ナットとボルトの外観デザインにおいて、規格外の溝がある、

開口または五角形、七角形、九角形または特注の対応溝工具

盗難防止効果が非常に高い

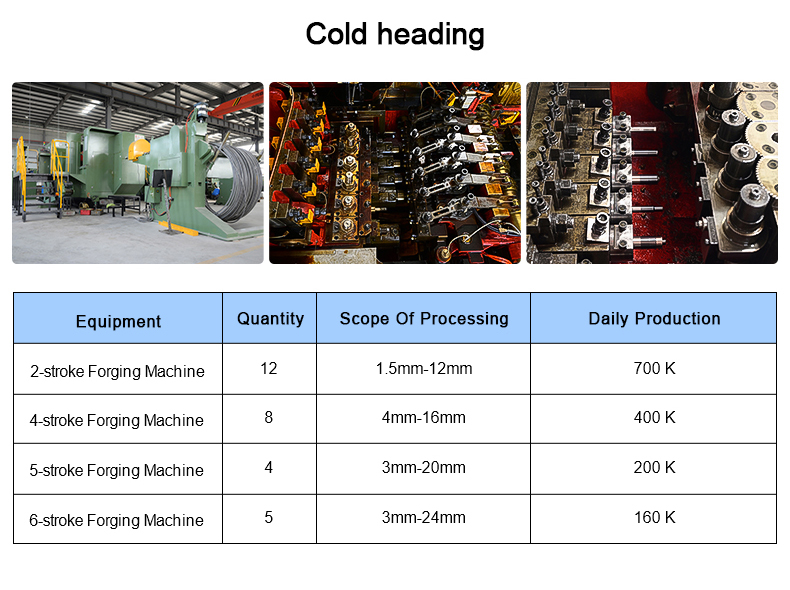

冷間圧造加工は、切削の少ない、あるいは切削を必要としない新しい圧造加工のひとつである。

の作用による金属の塑性変形を利用する加工法である。

外力を受け、金型の助けを借りて、金属の体積を再分配し、移動させる。

必要な部品やブランクを製造します。冷間圧造工程は、標準的な

ボルト、ネジ、ナット、リベット、ピンなどの留め具。

A ロック 木の実 は、振動やトルクなど、標準的なナットでは緩んでしまうような機械的な力による緩みを防ぐために設計された特殊ナットです。特に高振動環境など、確実な締結が不可欠な産業や用途では重要な部品です。

ロックナットの種類:

-

ナイロンインサートロックナット(ナイロックナット):

- ボルトやスクリューをグリップし、摩擦を与えて緩みを防止するナイロン製インサートを採用。

- 自動車、航空宇宙、一般機械用途によく使用される。

-

オールメタル・ロックナット:

- 完全に金属で作られたロックナットは、金属の変形を利用して、ファスナーのネジ山との摩擦を生み出す。

- 耐久性に優れ、高温や過酷な環境にも耐えることで知られる。

-

鋸歯状フランジロックナット:

- 鋸歯状のエッジを持つフランジを持ち、このエッジが素材やナットの表面に食い込むことで、緩みに対する抵抗力が増す。

- 高トルクを必要とする用途や、プラスチックやアルミニウムのような柔らかい素材にファスナーを固定する必要がある場合によく使用される。

-

常用トルク ロックナット:

- この設計では、内部の特徴(ナットの圧着部分など)を通してボルトに一定の圧力を加える。

- ナットの固定が必要だが、ネジ山を傷つけずに何度も締めたり調整したりする必要がある場合に使用。

材料:

- スチール:最も一般的で、強度とコストパフォーマンスに優れる。耐食性のための処理またはコーティングが可能(亜鉛メッキなど)。

- ステンレス鋼:腐食環境で使用され、錆や腐食に対してより高い耐性を提供する。

- 真鍮またはアルミニウム:耐食性に優れ、軽量な材料を必要とする用途。

アプリケーション:

- 自動車:エンジン、サスペンション、その他振動や高トルクにさらされる部品(ホイールナットやドライブシャフトなど)。

- 産業機器:機械の部品の固定に使用され、常に動きや振動のある場所での緩みを防止する。

- 航空宇宙:航空機や航空宇宙部品で、高速飛行や過酷な条件下でもファスナーが確実に固定されるようにする。

- 建設:振動にさらされる構造部品や機械の重荷重締結用。

メリット:

- ゆるみを防ぐ:振動や移動による不慮の分解を防ぎ、信頼性の高い確実な固定を提供します。

- 耐久性と強度:強いストレス、高トルク、振動に耐える強靭な素材を使用。

- 再利用性:多くのロックナット、特にナイロンインサートタイプは、ロック能力を失うことなく数回再利用することができる。

- 費用対効果の高いソリューション:より高価で特殊なロック機構の必要性を減らす。

- 汎用性:様々な用途や環境に対応するため、様々なサイズ、材質、ネジの種類があります。

考察:

- 温度感受性:ナイロン製インサート・ロックナットは、非常に高い温度(250℃以上)で劣化したり、効果を失う可能性があるため、極端な条件下では全金属製ロックナットのような代替品が必要になる場合がある。

- スペースの制約:オールメタル・タイプのようにコンパクトにできるロック・ナットもあるが、ナイロン・インサート・タイプのようにスペースを必要とするものもある。

レビュー

レビューはまだありません。