ボルトとナットの締結と開放は、非標準的な設計を採用し、一致する。

非標準の工具は、開口部と締結部の問題を解決するために使用される。一般的に、他の

レンチを挿入することはできません。ナットとボルトの外観デザインでは、非標準のスロット、

開口または五角形、七角形、九角形または特注の対応溝工具

盗難防止効果が非常に高い

冷間圧造加工は、切削の少ない、あるいは切削を必要としない新しい圧造加工のひとつである。

金属。の作用による金属の塑性変形を利用した加工法である。

外力を受け、金型の助けを借りて、金属の体積を再分配し、移動させる。

必要な部品やブランクを製造します。冷間圧造工程は、標準的な

ボルト、ネジ、ナット、リベット、ピンなどの留め具。

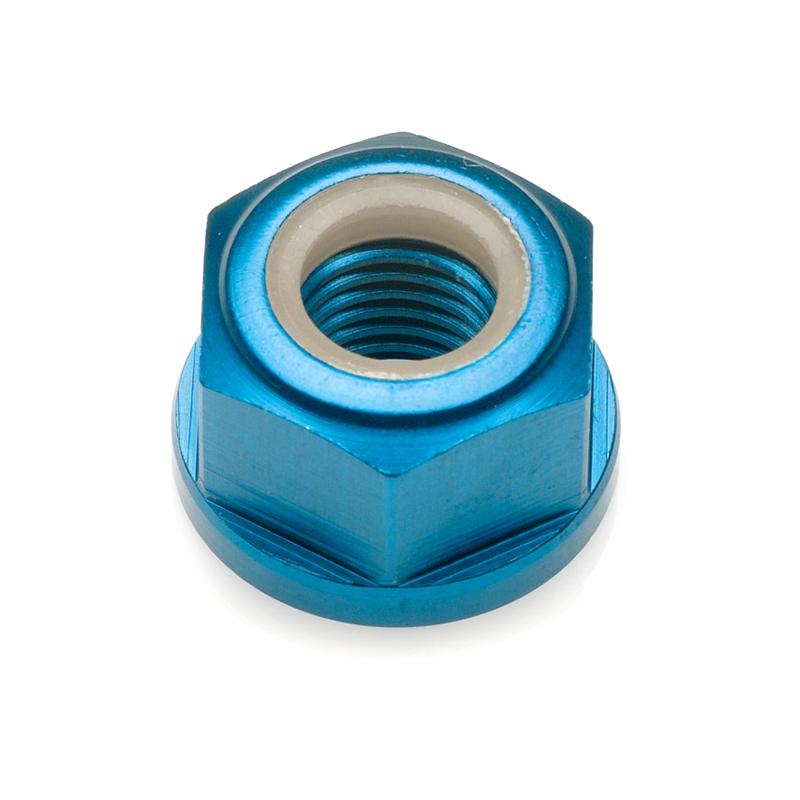

チタン ナットロック の特徴は、高強度、耐食性、および要求の厳しいアプリケーションで安全なロック機能を提供するように設計された特殊なファスナーです。これらのナットは、一般的に耐振動性と耐久性が重要である航空宇宙、自動車、海洋、および産業環境で使用されています。

チタン合金ロッキングナットの主な特徴:

-

素材構成

-

などの高級チタン合金から作られている。 Ti-6Al-4V (グレード 5) または Ti-6Al-4V ELI (グレード 23).

-

優れた強度対重量比、耐食性、生体適合性を提供。

-

-

ロック機構

-

金属製のロック機能: 通常、振動による緩みを防止するため、ナイロンを使用しない全金属製のロックシステム(変形スレッド、フランジ設計、または実勢トルク機能など)が含まれる。

-

一般的なタイプ:

-

常用トルクロックナット (例:全金属製の堅いナット)

-

ツーピースロックナット (フリースピンのカラーとロッキングインサート付き)

-

フランジ付き鋸歯状ナット (グリップ用セレーション付き)

-

-

-

メリット

-

高温耐性: 過酷な環境でも優れた性能を発揮する(高温で劣化するナイロン製インサートとは異なる)。

-

耐振動性: 動的用途での自己ゆるみを防止。

-

軽量だ: 航空宇宙や高性能車に最適。

-

非磁性・耐食性: 海洋および医療用途に適している。

-

-

一般的なアプリケーション

-

航空機・宇宙船部品

-

高性能自動車システム

-

軍事・防衛装備品

-

化学処理および海洋設備

-

医療用インプラントおよび器具(生体適合グレードから作られた場合)

-

-

規格と仕様

-

航空宇宙 NAS、MS、AN、ミルスペック

-

産業用だ: DIN、ISO、ASTM

-

自動車: カスタム高性能仕様

-

他のロッキングナットとの比較

-

ナイロンインサートナット(Nyloc): 安価だが、高温で劣化する。

-

ステンレススチール製ロックナット: チタンよりも重く、耐食性に劣る。

-

真鍮または銅のロックナット: より柔らかく、耐久性に劣る。

結論

チタンナット金属ロックは、軽量化、強度、耐振動性が不可欠な重要な用途向けのプレミアムファスナーです。そのオールメタルロック設計は、プラスチックベースのロック機構が故障するような過酷な条件下でも信頼性を保証します。

レビュー

レビューはまだありません。