冷間圧造加工は、切削の少ない、あるいは切削を必要としない新しい圧造加工のひとつである。

金属。の作用による金属の塑性変形を利用した加工法である。

外力を受け、金型の助けを借りて、金属の体積を再分配し、移動させる。

必要な部品やブランクを製造します。冷間圧造工程は、標準的な

ボルト、ネジ、ナット、リベット、ピンなどの留め具。

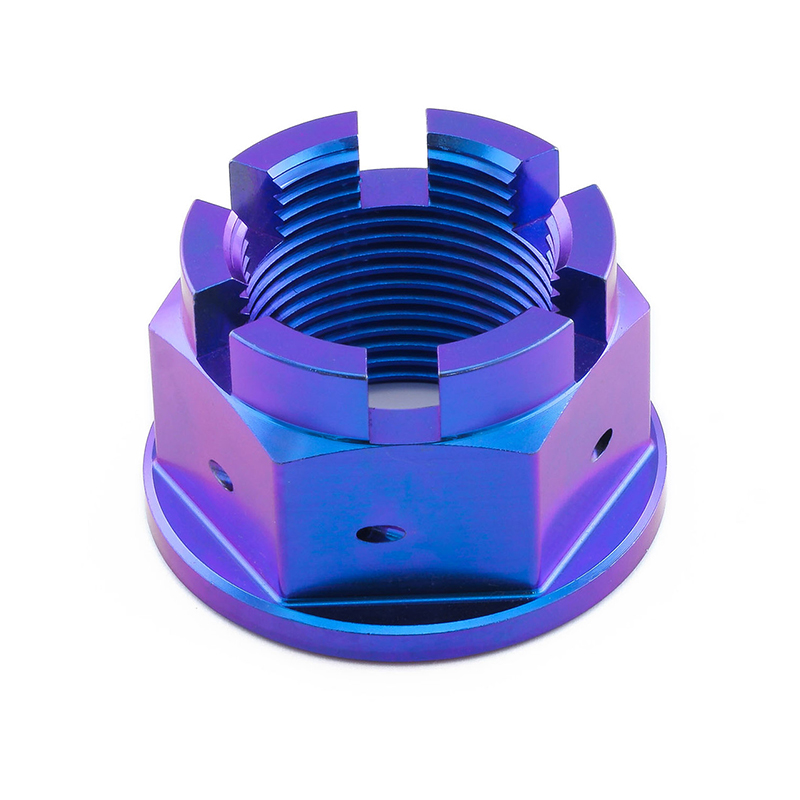

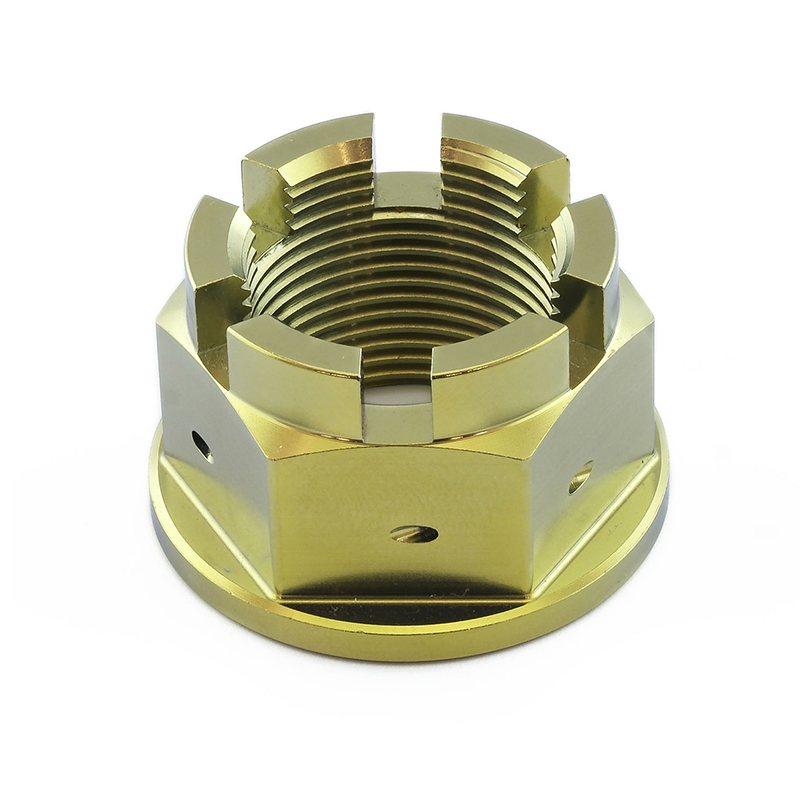

について セーフティライン用紫色メッキ歯付ナット は、視認性、耐食性、確実なロックが不可欠な用途向けに設計された特殊ファスナーです。ここでは、その主な特徴について全体的に説明する:

1.紫メッキ

-

ナットの特徴 パープル電気メッキ仕上げと規定している:

-

耐食性:サビや環境劣化から守る。

-

高い視認性:紫色は、迅速な識別と検査に役立ち、セーフティクリティカルな用途に有用。

-

美的アピール:色分けが重要な産業でよく使用される。

- 歯付きナット 紫メッキ

-

2.歯のデザイン(鋸歯状フランジまたは歯)

-

ナットには 一体型歯またはセレーション ベアリングの表面(通常はヘッドまたはフランジの下)にある:

-

緩みを防ぐ:歯が相手面に食い込み、振動やトルクに耐える。

-

ワッシャーの必要性をなくす:セレーションは内蔵のロック機構として機能する。

-

3.セーフティライン機能

-

バージョンによっては 安全ラインまたはマーキング (例えば、色のついたストライプ)により、適切なトルクを示したり、経時的なゆるみを検出したりする。

4.素材と強度

-

一般的には、以下の材料で作られている。 炭素鋼、合金鋼、またはステンレス鋼.

-

以下のような業界標準を満たす可能性がある。 DIN、ISO、またはANSI 機械的特性(グレード8、クラス10など)。

- 歯付きナット 紫メッキ

5.共通アプリケーション

-

自動車・航空宇宙:高振動環境

-

鉄道・重機:動的荷重下での確実な固定。

-

電気・通信:安全確認のための色分け。

-

建設・インフラ:耐腐食性屋外使用。

6.規格とコンプライアンス

-

適合する可能性 DIN 6923 (フランジセレーションナット), ISO 7040またはその他の業界固有の資格

このナットは、以下を必要とする産業に理想的である。 安全遵守のための視覚インジケータを備えた高セキュリティ・ファスナー.特定の規格やアプリケーションの詳細をお知りになりたいですか?

レビュー

レビューはまだありません。