A fixação e abertura de parafusos e porcas adopta um design não normalizado, e a correspondência

são utilizadas ferramentas não normalizadas para resolver os problemas de abertura e de fixação. Em geral, outras

não podem ser inseridas chaves de bocas. Na conceção visual das porcas e parafusos, ranhuras não normalizadas,

ferramentas de abertura ou de ranhuras correspondentes pentagonais, heptagonais, de nove cantos ou feitas por medida

têm um efeito antirroubo muito bom

O processo de encabeçamento a frio é um dos novos processos para a maquinagem sob pressão com menos ou nenhum corte

metal. É um método de processamento que utiliza a deformação plástica do metal sob a ação de

forças externas e, com a ajuda de moldes, redistribui e transfere o volume de metal para formar

as peças ou os espaços em branco necessários. O processo de encabeçamento a frio é o mais adequado para a produção de

elementos de fixação, tais como cavilhas, parafusos, porcas, rebites, cavilhas, etc.

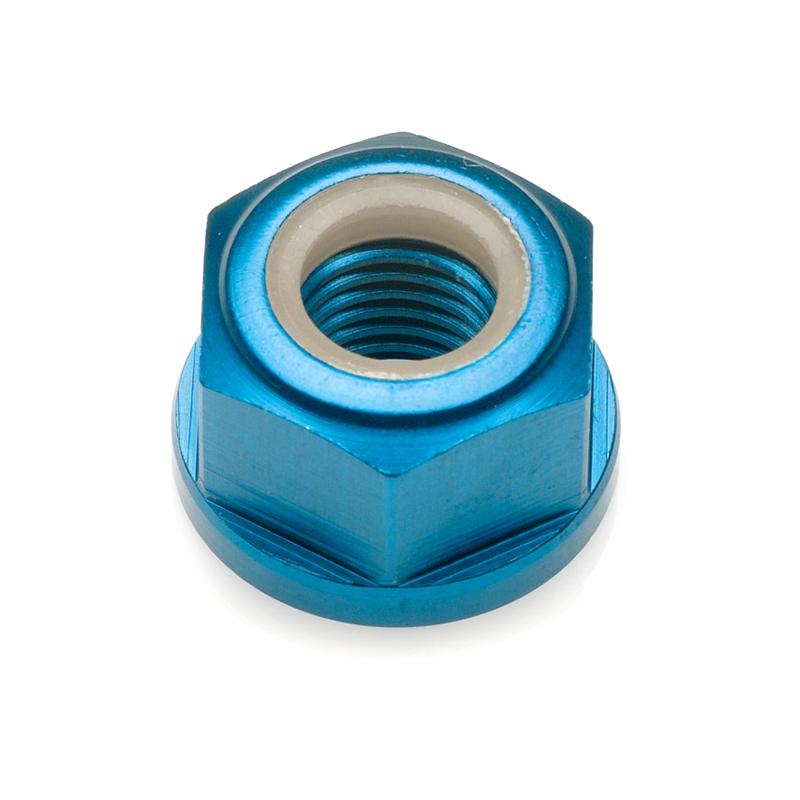

Um alumínio nozes O óxido vermelho é um elemento de fixação que foi submetido a um tratamento de superfície para obter um acabamento de cor vermelha, normalmente através de anodização, tingimento químico, ou revestimentos de óxido especializados. Este processo melhora tanto a estética como a funcionalidade. Segue-se uma descrição pormenorizada:

1. Material

-

Fabricado em ligas de alumínio (classes comuns: 6061-T6, 2024, ou 7075 para força e resistência à corrosão).

2. Processo de óxido vermelho

Vermelho anodizado

-

Anodização com ácido sulfúrico (Tipo II) - A porca de alumínio é anodizada para criar uma camada de óxido poroso e depois tingida vermelho utilizando corantes orgânicos ou inorgânicos antes da selagem.

-

Anodização dura (Tipo III) - Produz uma camada mais espessa e durável, resultando por vezes numa tonalidade vermelha mais profunda ou cor de vinho.

Revestimento de conversão de cromato vermelho

-

Um tratamento químico (por exemplo, Alodine/MIL-DTL-5541) que deposita um dourado-avermelhado ou óxido vermelho camada.

-

Proporciona resistência à corrosão, mantendo a condutividade eléctrica.

Revestimentos especializados de óxido vermelho

-

Alguns fabricantes aplicam à base de cerâmica ou com infusão de epóxi revestimentos vermelhos para ambientes extremos.

3. Caraterísticas e vantagens

-

Resistência à corrosão - Protege contra a oxidação, salinidade e produtos químicos.

-

Alta visibilidade - A cor vermelha é útil para marcações de segurança ou identificação de montagem.

-

Apelo decorativo - Utilizado em produtos de consumo, automóveis e construções personalizadas.

-

Leve - Mantém a relação resistência/peso do alumínio.

4. Aplicações comuns

-

Aeroespacial e Defesa - Porcas anodizadas vermelhas para montagens críticas ou de alta visibilidade.

-

Automóvel e Corridas - Fixadores vermelhos personalizados para compartimentos de motor ou peças de suspensão.

-

Eletrónica - Porcas com código de cores em placas de circuitos ou máquinas.

-

Equipamento marítimo e de exterior - Maior resistência às intempéries com um aspeto arrojado.

5. Variações do acabamento vermelho

-

Vermelho vivo - Obtido com corantes orgânicos em anodização (comum para utilizações decorativas).

-

Vermelho escuro/Borgonha - Resultado de uma imersão mais longa em corante ou de uma anodização dura.

-

Mate ou brilhante - Depende da preparação da superfície (por exemplo, jato de areia para mate, polimento para brilho).

6. Limitações

-

Sensibilidade aos raios UV - Os corantes vermelhos podem desvanecer-se com o tempo se não forem devidamente selados.

-

Força inferior - As porcas de alumínio não são adequadas para aplicações de binário elevado como as de aço.

-

Restrições químicas - Alguns cromatos vermelhos contêm substâncias regulamentadas (por exemplo, crómio hexavalente).

Normas do sector

-

Anodização: MIL-A-8625 (Tipo II/III)

-

Revestimento de cromato: MIL-DTL-5541 (Classe 1A para crómio hexavalente, Classe 3 para alternativas compatíveis com RoHS)

Avaliações

Ainda não existem avaliações.