A fixação e abertura de parafusos e porcas adopta um design não normalizado, e a correspondência

são utilizadas ferramentas não normalizadas para resolver os problemas de abertura e de fixação. Em geral, outras

não podem ser inseridas chaves de bocas. Na conceção visual das porcas e parafusos, ranhuras não normalizadas,

ferramentas de abertura ou de ranhuras correspondentes pentagonais, heptagonais, de nove cantos ou feitas por medida

têm um efeito antirroubo muito bom

O processo de encabeçamento a frio é um dos novos processos para a maquinagem sob pressão com menos ou nenhum corte

metal. É um método de processamento que utiliza a deformação plástica do metal sob a ação de

forças externas e, com a ajuda de moldes, redistribui e transfere o volume de metal para formar

as peças ou os espaços em branco necessários. O processo de encabeçamento a frio é o mais adequado para a produção de

elementos de fixação, tais como cavilhas, parafusos, porcas, rebites, cavilhas, etc.

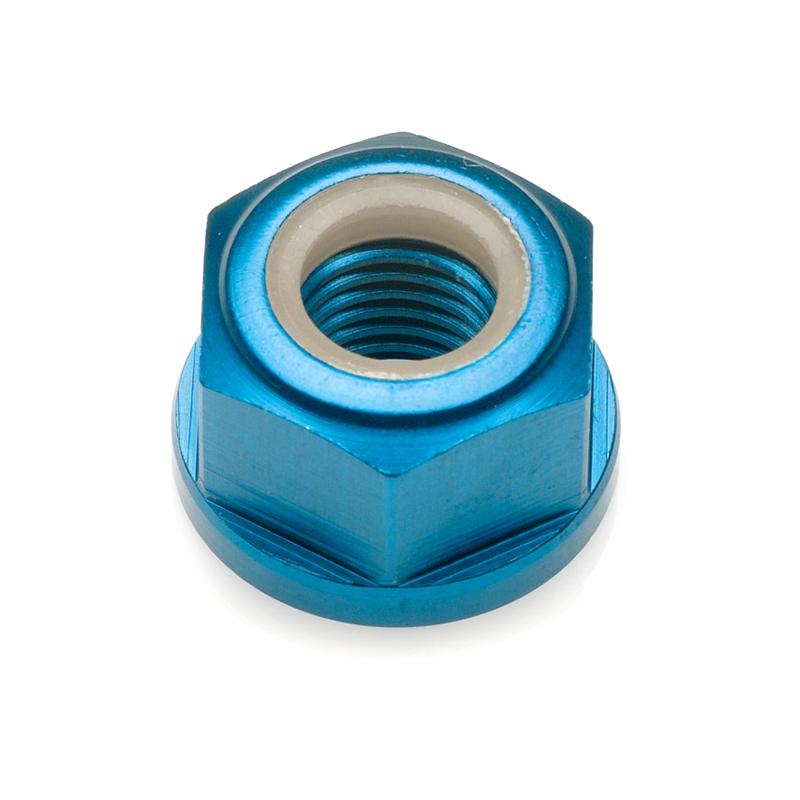

Titânio porca metálica de bloqueio são elementos de fixação especializados concebidos para proporcionar elevada resistência, resistência à corrosão e capacidades de bloqueio seguro em aplicações exigentes. Estas porcas são normalmente utilizadas nos sectores aeroespacial, automóvel, marítimo e industrial, onde a resistência à vibração e a durabilidade são fundamentais.

Caraterísticas principais das porcas de bloqueio em liga de titânio:

-

Composição do material

-

Fabricado a partir de ligas de titânio de alta qualidade, tais como Ti-6Al-4V (Grau 5) ou Ti-6Al-4V ELI (Grau 23).

-

Oferece uma excelente relação força/peso, resistência à corrosão e biocompatibilidade.

-

-

Mecanismo de bloqueio

-

Metal Função de bloqueio: Inclui normalmente um sistema de bloqueio totalmente metálico e sem nylon (por exemplo, roscas deformadas, design flangeado ou uma caraterística de binário predominante) para evitar o afrouxamento sob vibração.

-

Tipos comuns:

-

Porcas de bloqueio de binário prevalecente (por exemplo, porcas rígidas totalmente metálicas)

-

Porcas de bloqueio de duas peças (com um colar de rotação livre e um encaixe de bloqueio)

-

Porcas serrilhadas flangeadas (com serrilhas para agarrar)

-

-

-

Vantagens

-

Resistência a altas temperaturas: Tem um bom desempenho em ambientes extremos (ao contrário das pastilhas de nylon, que se degradam a temperaturas elevadas).

-

Resistência à vibração: Evita o auto-afrouxamento em aplicações dinâmicas.

-

Leve: Ideal para veículos aeroespaciais e de desempenho.

-

Não magnético e resistente à corrosão: Adequado para aplicações marítimas e médicas.

-

-

Aplicações comuns

-

Componentes de aeronaves e de veículos espaciais

-

Sistemas automóveis de elevado desempenho

-

Equipamento militar e de defesa

-

Processamento químico e instalações offshore

-

Implantes e dispositivos médicos (se fabricados com materiais biocompatíveis)

-

-

Normas e especificações

-

Aeroespacial: NAS, MS, AN, MIL-SPEC

-

Industrial: DIN, ISO, ASTM

-

Automóvel: Especificações personalizadas de alto desempenho

-

Comparação com outras porcas de bloqueio

-

Porcas de inserção de nylon (Nyloc): Mais baratos, mas degradam-se a temperaturas elevadas.

-

Porcas de bloqueio em aço inoxidável: Mais pesado e menos resistente à corrosão do que o titânio.

-

Porcas de bloqueio em latão ou cobre: Mais macio e menos durável.

Conclusão

Os fechos metálicos com porca de titânio são fixadores de primeira qualidade para aplicações críticas em que a redução de peso, a força e a resistência à vibração são essenciais. O seu design de bloqueio totalmente metálico garante fiabilidade em condições extremas em que os mecanismos de bloqueio à base de plástico falhariam.

Avaliações

Ainda não existem avaliações.