يعتمد تثبيت البراغي والصواميل وفتحها على تصميم غير قياسي، ومطابقة

تُستخدم أدوات غير قياسية لحل مشاكل الفتح والتثبيت. وبصفة عامة، فإن

لا يمكن إدخال مفاتيح الربط. في تصميم مظهر الصواميل والمسامير، الشق غير القياسي,

أدوات فتح أو خماسية أو خماسية أو سباعية أو تساعية الزوايا أو أدوات الأخدود المقابلة المصنوعة حسب الطلب

لعبت تأثيرًا جيدًا جدًا في مكافحة السرقة

عملية الرأس على البارد هي واحدة من العمليات الجديدة للتشغيل الآلي بالضغط ذات القطع الأقل أو بدون قطع

المعدن. وهي طريقة معالجة تستخدم التشوه البلاستيكي للمعدن تحت تأثير

قوى خارجية، وبمساعدة القوالب، تقوم بإعادة توزيع ونقل حجم المعدن لتشكيل

الأجزاء أو الفراغات المطلوبة. عملية الخراطة على البارد هي الأكثر ملاءمة لإنتاج الأجزاء القياسية

أدوات التثبيت مثل البراغي والبراغي والصواميل والمسامير والمسامير والدبابيس وغيرها

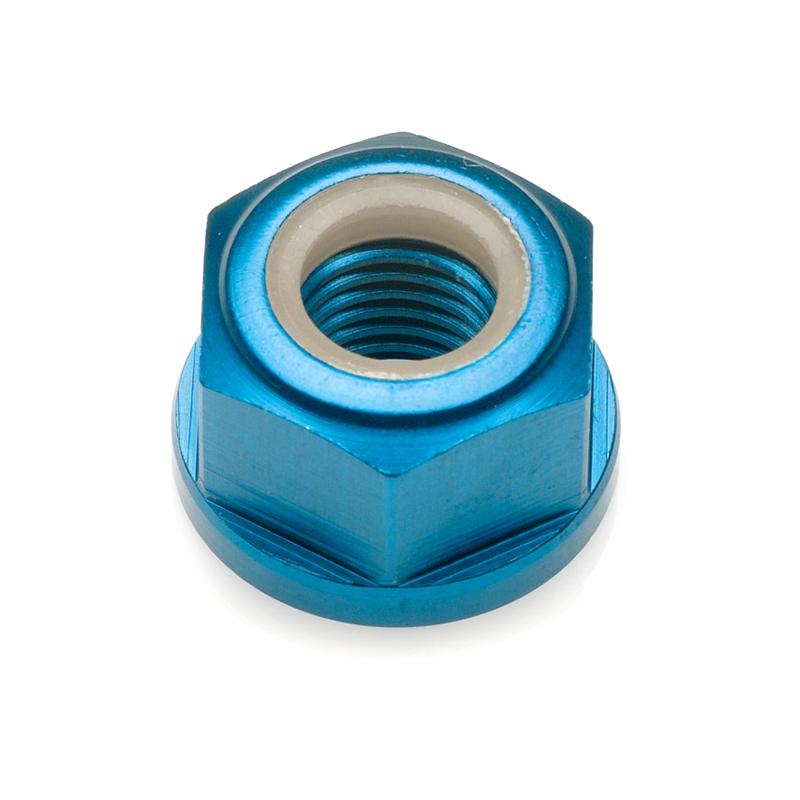

ألومنيوم المكسرات الأكسيد الأحمر عبارة عن قفل خضع لمعالجة سطحية للحصول على لون أحمر، عادةً من خلال الطلاء بأكسيد الألومنيوم, الصباغة الكيميائيةأو طلاءات الأكسيد المتخصصة. تعمل هذه العملية على تحسين كل من الجماليات والوظائف. وفيما يلي تفصيل مفصل:

1. المواد

-

مصنوعة من سبائك الألومنيوم (الدرجات الشائعة: 6061-T6 أو 2024 أو 7075 للقوة ومقاومة التآكل).

2. عملية الأكسيد الأحمر

أحمر مؤكسد

-

أنودة حمض الكبريتيك (النوع الثاني) - يتم طلاء صامولة الألومنيوم بأكسيد الألومنيوم لتكوين طبقة أكسيد مسامية، ثم يتم صبغها أحمر باستخدام الصبغات العضوية أو غير العضوية قبل الختم.

-

الأنودة الصلبة (النوع الثالث) - يُنتج طبقة أكثر سمكاً ومتانة، مما يؤدي أحياناً إلى الحصول على لون أحمر أو أحمر غامق أو عنابي أعمق.

طلاء محول الكرومات الأحمر

-

معالجة كيميائية (على سبيل المثال, ألودين/ميل-دي تي إل-5541) التي تودع ذهب محمر-ذهبي أو الأكسيد الأحمر الطبقة.

-

يوفر مقاومة للتآكل مع الحفاظ على التوصيل الكهربائي.

طلاءات الأكسيد الأحمر المتخصصة

-

تطبق بعض الشركات المصنعة السيراميك أو الإيبوكسي المشبع بالإيبوكسي طلاءات حمراء للبيئات القاسية.

3. الميزات والفوائد

-

مقاومة التآكل - يحمي من الأكسدة ورذاذ الملح والمواد الكيميائية.

-

رؤية عالية الوضوح - اللون الأحمر مفيد لعلامات السلامة أو تعريف التجميع.

-

جاذبية الديكور - تُستخدم في المنتجات الاستهلاكية والسيارات والتصنيع حسب الطلب.

-

خفيف الوزن - يحافظ على نسبة قوة الألومنيوم إلى الوزن.

4. التطبيقات الشائعة

-

الطيران والفضاء والدفاع - صواميل مؤكسدة حمراء للتركيبات عالية الوضوح أو الحرجة.

-

السيارات والسباقات - مثبتات حمراء مخصصة لخلجان المحرك أو أجزاء التعليق.

-

الإلكترونيات - صواميل مرمزة بالألوان في لوحات الدوائر أو الآلات.

-

معدات بحرية وخارجية - مقاومة محسّنة للعوامل الجوية مع مظهر جريء.

5. الاختلافات في اللمسة النهائية الحمراء

-

أحمر فاتح - يتم تحقيقه باستخدام الأصباغ العضوية في الأنودة (شائعة للاستخدامات الزخرفية).

-

أحمر غامق/عنابي - نتيجة غمر الصبغة لفترة أطول أو الطلاء بأكسيد الألومنيوم الصلب.

-

غير لامع أو غير لامع - يعتمد ذلك على إعداد السطح (على سبيل المثال، السفع بالخرز للتلميع غير اللامع والتلميع لللمعان).

6. القيود

-

حساسية الأشعة فوق البنفسجية - قد تتلاشى الصبغات الحمراء بمرور الوقت إذا لم يتم إغلاقها بشكل صحيح.

-

قوة أقل - صواميل الألومنيوم غير مناسبة للاستخدامات عالية العزم مثل الفولاذ.

-

القيود الكيميائية - تحتوي بعض الكرومات الحمراء على مواد منظمة (مثل الكروم سداسي التكافؤ).

معايير الصناعة

-

الطلاء بأكسيد الألمنيوم: MIL-A-8625 (النوع الثاني/الثالث)

-

طلاء بالكرومات: MIL-DTL-5541 (الفئة 1A للكروم سداسي التكافؤ، والفئة 3 للبدائل المتوافقة مع RoHS)

المراجعات

لا توجد مراجعات بعد.