يعتمد تثبيت البراغي والصواميل وفتحها على تصميم غير قياسي، ومطابقة

تُستخدم أدوات غير قياسية لحل مشاكل الفتح والتثبيت. وبصفة عامة، فإن

لا يمكن إدخال مفاتيح الربط. في تصميم مظهر الصواميل والمسامير، الشق غير القياسي,

أدوات فتح أو خماسية أو خماسية أو سباعية أو تساعية الزوايا أو أدوات الأخدود المقابلة المصنوعة حسب الطلب

لعبت تأثيرًا جيدًا جدًا في مكافحة السرقة

عملية الرأس على البارد هي واحدة من العمليات الجديدة للتشغيل الآلي بالضغط ذات القطع الأقل أو بدون قطع

المعدن. وهي طريقة معالجة تستخدم التشوه البلاستيكي للمعدن تحت تأثير

قوى خارجية، وبمساعدة القوالب، تقوم بإعادة توزيع ونقل حجم المعدن لتشكيل

الأجزاء أو الفراغات المطلوبة. عملية الخراطة على البارد هي الأكثر ملاءمة لإنتاج الأجزاء القياسية

أدوات التثبيت مثل البراغي والبراغي والصواميل والمسامير والمسامير والدبابيس وغيرها

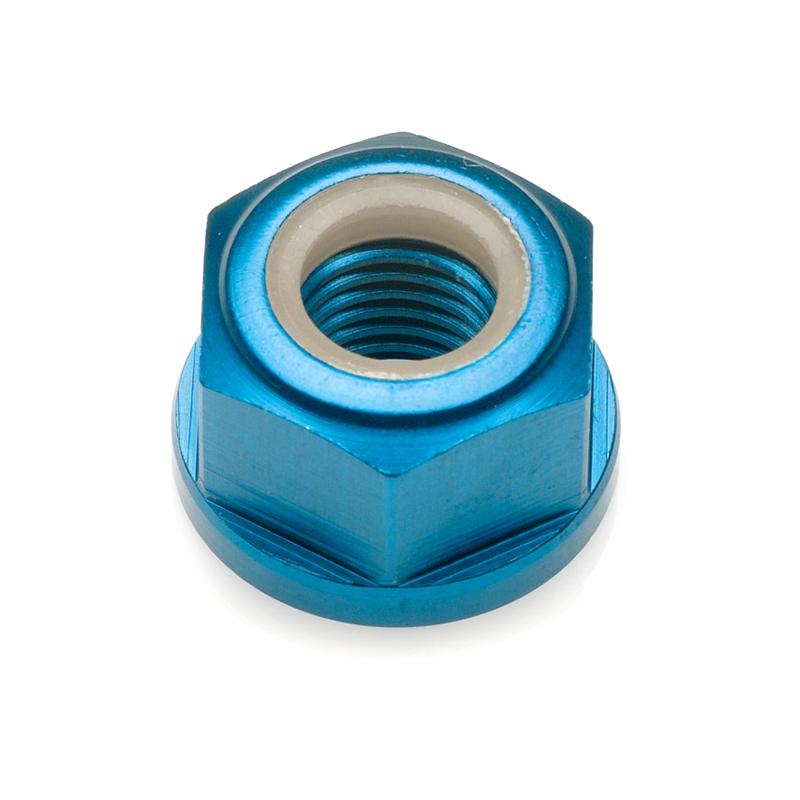

تيتانيوم قفل معدني صامولة القفل الميزات عبارة عن مثبتات متخصصة مصممة لتوفير قوة عالية ومقاومة للتآكل وقدرات قفل آمنة في التطبيقات الصعبة. تُستخدم هذه الصواميل عادةً في صناعة الطيران والسيارات والمعدات البحرية والصناعية حيث تكون مقاومة الاهتزازات والمتانة أمرًا بالغ الأهمية.

الميزات الرئيسية لصواميل القفل المصنوعة من سبائك التيتانيوم:

-

التركيب المادي

-

مصنوعة من سبائك التيتانيوم عالية الجودة مثل Ti-6Al-4V (الدرجة 5) أو Ti-6Al-4V ELI (الصف 23).

-

يوفر نسبة ممتازة من القوة إلى الوزن ومقاومة التآكل والتوافق الحيوي.

-

-

آلية القفل

-

خاصية القفل المعدني: عادةً ما يتضمن نظام قفل معدني بالكامل خالٍ من النايلون (على سبيل المثال، اللوالب المشوهة، أو تصميم ذو حواف، أو خاصية عزم الدوران السائد) لمنع الارتخاء تحت الاهتزاز.

-

الأنواع الشائعة:

-

صواميل قفل عزم الدوران السائدة (على سبيل المثال، صواميل صلبة معدنية بالكامل)

-

صواميل القفل المكونة من قطعتين (مع طوق حر الدوران وإدخال قفل)

-

صواميل مسننة ذات حواف مسننة (مع مسننات للإمساك)

-

-

-

المزايا

-

مقاومة درجات الحرارة العالية: أداء جيد في البيئات القاسية (على عكس حشوات النايلون التي تتحلل في درجات الحرارة العالية).

-

مقاومة الاهتزازات: يمنع الارتخاء الذاتي في التطبيقات الديناميكية.

-

خفيف الوزن: مثالية للمركبات الفضائية والمركبات عالية الأداء.

-

غير مغناطيسية ومقاومة للتآكل: مناسبة للاستخدامات البحرية والطبية.

-

-

التطبيقات الشائعة

-

مكونات الطائرات والمركبات الفضائية

-

أنظمة السيارات عالية الأداء

-

المعدات العسكرية والدفاعية

-

المعالجة الكيميائية والمنشآت البحرية

-

الغرسات والأجهزة الطبية (إذا كانت مصنوعة من درجات متوافقة حيوياً)

-

-

المعايير والمواصفات

-

الفضاء الجوي: ناس، م.م.س، م.م.س، م.م.أ، م.م.م.م.م.م.م.م.أ

-

صناعي: DIN، ISO، ASTM

-

السيارات: مواصفات مخصصة عالية الأداء

-

مقارنة مع صواميل القفل الأخرى

-

صواميل إدراج النايلون (نايلوك): أرخص ولكن تتحلل في درجات الحرارة العالية.

-

صواميل قفل من الفولاذ المقاوم للصدأ: أثقل وأقل مقاومة للتآكل من التيتانيوم.

-

صواميل قفل نحاسية أو نحاسية: أنعم وأقل متانة.

الخاتمة

القفل المعدني بالصامولة المصنوعة من التيتانيوم عبارة عن مثبتات ممتازة للتطبيقات الحرجة حيث يكون توفير الوزن والقوة ومقاومة الاهتزازات أمورًا ضرورية. يضمن تصميم قفلها المعدني بالكامل الموثوقية في الظروف القاسية التي قد تفشل فيها آليات القفل القائمة على البلاستيك.

المراجعات

لا توجد مراجعات بعد.