La fijación y apertura de pernos y tuercas adopta un diseño no estándar, y la coincidencia

Para resolver los problemas de apertura y fijación se utilizan herramientas no estándar. En general, se utilizan otras

no se pueden insertar llaves. En el diseño de apariencia de tuercas y tornillos, ranurado no estándar,

apertura o herramientas de ranura pentagonal, heptagonal, de nueve esquinas o a medida correspondiente

han desempeñado un muy buen efecto antirrobo

El proceso de estampado en frío es uno de los nuevos procesos de mecanizado a presión de menor o ningún corte

metal. Es un método de transformación que utiliza la deformación plástica del metal bajo la acción de

fuerzas externas y, con ayuda de moldes, redistribuye y transfiere el volumen de metal para formar

las piezas o formatos necesarios. El proceso de estampación en frío es el más adecuado para producir piezas estándar.

elementos de fijación como pernos, tornillos, tuercas, remaches, pasadores, etc.

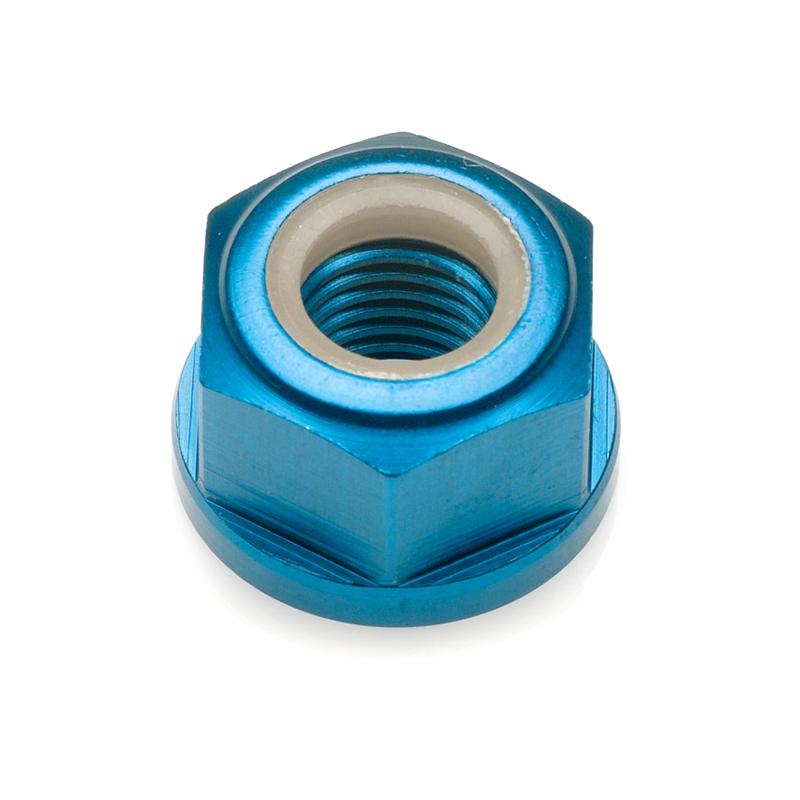

Tuerca de aluminio con óxido azul Revestimiento - Descripción

Tuercas de aluminio con recubrimiento de óxido azul son fijaciones ligeras y resistentes a la corrosión diseñadas para aplicaciones en las que el ahorro de peso y el atractivo estético son importantes. El acabado de óxido azul proporciona una capa decorativa y ligeramente protectora a la vez que mantiene la conductividad y las propiedades no magnéticas de la tuerca.

Características principales:

-

Material:

-

Hecho de aleaciones de aluminio (normalmente 6061-T6 o 7075-T6 para una mayor resistencia).

-

Ligero (~1/3 del peso del acero) con buena resistencia a la corrosión.

-

-

Revestimiento de óxido azul:

-

A revestimiento de conversión química (no anodizado) que proporciona:

-

Ligera resistencia a la corrosión (menos que el anodizado pero mejor que el aluminio desnudo).

-

Acabado decorativo azul-negro (con fines estéticos o de codificación por colores).

-

Interferencias no conductoras (a diferencia del anodizado, que puede afectar a la conductividad).

-

-

Más fino que el anodizado, por lo que no altera significativamente las dimensiones de la rosca.

-

-

Mecanismo de cierre (si procede):

-

Algunas tuercas de aluminio de óxido azul pueden incluir:

-

Inserto de nylon (Nyloc) para la resistencia a las vibraciones.

-

Brida dentada para un mejor agarre.

-

Diseño de par predominante (cierre totalmente metálico).

-

-

-

Ventajas:

-

Ligero - Ideal para aplicaciones aeroespaciales, de automoción y ciclismo.

-

No magnético y conductor - Se utiliza en aplicaciones electrónicas y de radiofrecuencia.

-

Atractivo estético - A menudo se utiliza en construcciones personalizadas, motocicletas y drones.

-

Resistencia moderada a la corrosión - Adecuado para uso en interiores o exteriores suaves.

-

-

Limitaciones:

-

No son tan resistentes a la corrosión como las tuercas anodizadas o de acero inoxidable.

-

Menor resistencia en comparación con el acero o el titanio.

-

El óxido azul puede desgastarse con el tiempo debido a la fricción.

-

Aplicaciones comunes:

-

Aeroespacial y drones (conjuntos sensibles al peso).

-

Automóviles y motocicletas personalizados (cierres decorativos).

-

Armarios eléctricos y electrónicos (propiedades no magnéticas y conductoras).

-

Bicicletas y material deportivo (componentes ligeros).

Conclusión:

Las tuercas de aluminio con óxido azul son una buena elección para aplicaciones ligeras y no magnéticas en las que se desea una resistencia moderada a la corrosión y un acabado atractivo. Sin embargo, para entornos más duros, tuercas anodizadas o de acero inoxidable puede ser más adecuado.

Valoraciones

No hay valoraciones aún.