La fijación y apertura de pernos y tuercas adopta un diseño no estándar, y la coincidencia

Para resolver los problemas de apertura y fijación se utilizan herramientas no estándar. En general, se utilizan otras

no se pueden insertar llaves. En el diseño de apariencia de tuercas y tornillos, ranurado no estándar,

apertura o herramientas de ranura pentagonal, heptagonal, de nueve esquinas o a medida correspondiente

han desempeñado un muy buen efecto antirrobo

El proceso de estampado en frío es uno de los nuevos procesos de mecanizado a presión de menor o ningún corte

metal. Es un método de transformación que utiliza la deformación plástica del metal bajo la acción de

fuerzas externas y, con ayuda de moldes, redistribuye y transfiere el volumen de metal para formar

las piezas o formatos necesarios. El proceso de estampación en frío es el más adecuado para producir piezas estándar.

elementos de fijación como pernos, tornillos, tuercas, remaches, pasadores, etc.

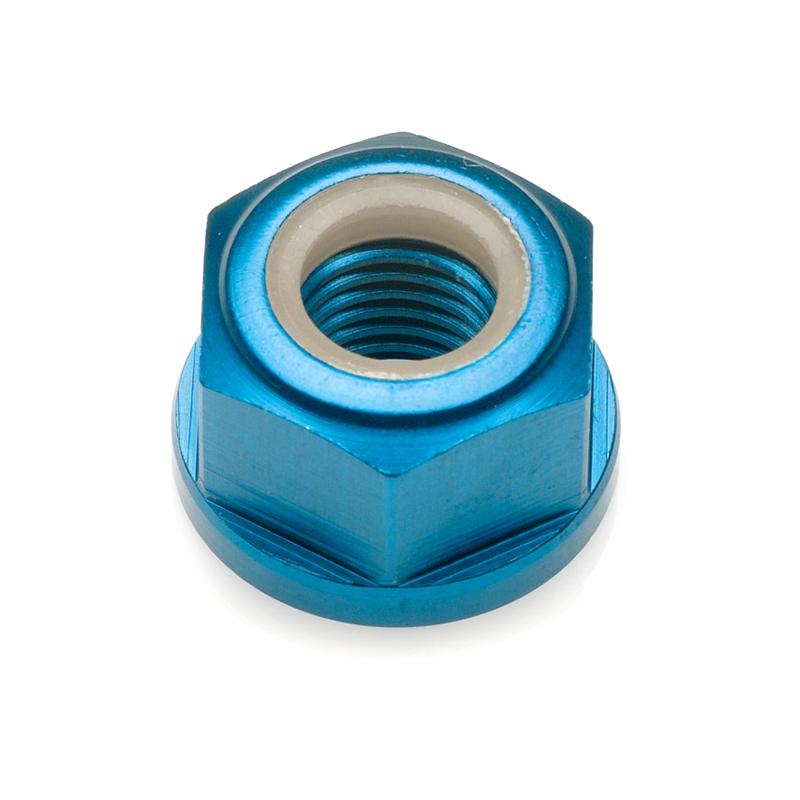

Un aluminio nueces El óxido rojo es un elemento de fijación que ha sido sometido a un tratamiento superficial para conseguir un acabado de color rojo, normalmente mediante anodizado, teñido químicoo recubrimientos de óxido especializados. Este proceso mejora tanto la estética como la funcionalidad. A continuación encontrará un desglose detallado:

1. Material

-

Hecho de aleaciones de aluminio (calidades habituales: 6061-T6, 2024 o 7075 para mayor solidez y resistencia a la corrosión).

2. Proceso del óxido rojo

Rojo anodizado

-

Anodizado con ácido sulfúrico (Tipo II) - La tuerca de aluminio se anodiza para crear una capa porosa de óxido y luego se tiñe rojo utilizando tintes orgánicos o inorgánicos antes del sellado.

-

Anodizado duro (Tipo III) - Produce una capa más gruesa y duradera, a veces con un tono rojo o burdeos más intenso.

Revestimiento de conversión al cromato rojo

-

Un tratamiento químico (p. ej, Alodina/MIL-DTL-5541) que deposita un oro rojizo o óxido rojo capa.

-

Proporciona resistencia a la corrosión manteniendo la conductividad eléctrica.

Revestimientos especializados de óxido rojo

-

Algunos fabricantes aplican con base cerámica o epoxy-infused revestimientos rojos para entornos extremos.

3. Características y ventajas

-

Resistencia a la corrosión - Protege contra la oxidación, la niebla salina y los productos químicos.

-

Alta visibilidad - El color rojo es útil para las marcas de seguridad o la identificación del montaje.

-

Atractivo decorativo - Se utiliza en productos de consumo, automoción y construcciones a medida.

-

Ligero - Mantiene la relación resistencia-peso del aluminio.

4. Aplicaciones comunes

-

Aeroespacial y defensa - Tuercas anodizadas en rojo para montajes de alta visibilidad o críticos.

-

Automoción y carreras - Fijaciones rojas personalizadas para vanos motor o piezas de suspensión.

-

Electrónica - Tuercas codificadas por colores en placas de circuitos o maquinaria.

-

Náutica y Outdoor - Mayor resistencia a la intemperie con un aspecto atrevido.

5. Variaciones en el acabado rojo

-

Rojo vivo - Se consigue con tintes orgánicos en anodizado (habitual para usos decorativos).

-

Rojo oscuro/burdeos - Resultado de una inmersión en tinte más prolongada o de un anodizado duro.

-

Mate o brillante - Depende de la preparación de la superficie (por ejemplo, granallado para mate, pulido para brillante).

6. Limitaciones

-

Sensibilidad UV - Los tintes rojos pueden desteñir con el tiempo si no se sellan correctamente.

-

Fuerza inferior - Las tuercas de aluminio no son adecuadas para aplicaciones de alto par como las de acero.

-

Restricciones químicas - Algunos cromatos rojos contienen sustancias reguladas (por ejemplo, cromo hexavalente).

Normas del sector

-

Anodizado: MIL-A-8625 (Tipo II/III)

-

Recubrimiento de cromato: MIL-DTL-5541 (Clase 1A para cromo hexavalente, Clase 3 para alternativas conformes con RoHS)

Valoraciones

No hay valoraciones aún.