El proceso de estampado en frío es uno de los nuevos procesos de mecanizado a presión de menor o ningún corte

metal. Es un método de transformación que utiliza la deformación plástica del metal bajo la acción de

fuerzas externas y, con ayuda de moldes, redistribuye y transfiere el volumen de metal para formar

las piezas o formatos necesarios. El proceso de estampación en frío es el más adecuado para producir piezas estándar.

elementos de fijación como pernos, tornillos, tuercas, remaches, pasadores, etc.

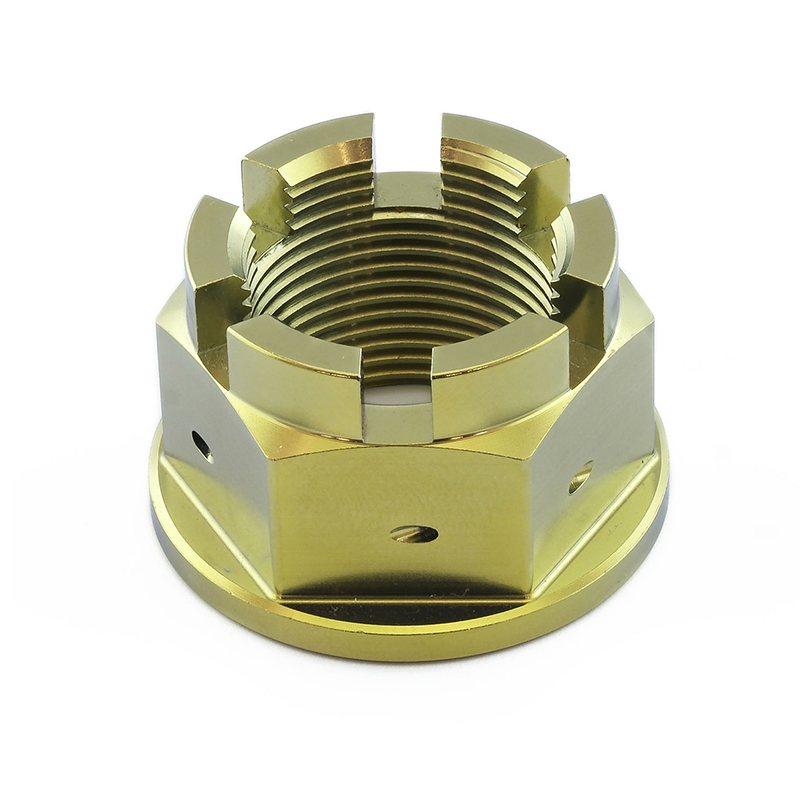

A cable de seguridad tuerca dentada cobreada es un cierre especializado diseñado para aplicaciones que requieren un bloqueo seguro para evitar que se afloje bajo vibraciones o cargas dinámicas. A continuación se ofrece una descripción general de sus principales características y usos:

Características principales:

-

Acabado cobreado

-

Proporciona resistencia a la corrosión y mejora la conductividad, por lo que es adecuado para aplicaciones de puesta a tierra eléctrica o apantallamiento EMI/RFI.

-

Mejora la durabilidad en entornos difíciles (por ejemplo, en la industria aeroespacial, automovilística o naval).

-

-

Diseño de los dientes (pestaña dentada o dientes bajo la tuerca)

-

La tuerca tiene estrías (dientes) en la superficie de apoyo que muerden el material de contacto, aumentando la resistencia a la rotación.

-

Garantiza un cierre hermético y resistente a las vibraciones sin necesidad de arandelas adicionales.

- Tuerca dentada cobreada

-

-

Orificios para cables de seguridad

-

Los orificios pretaladrados permiten fijar la tuerca con cable de seguridad (cable de bloqueo), utilizado habitualmente en aviación, deportes de motor y aplicaciones militares.

-

El alambre se enhebra a través de los cierres adyacentes para evitar que se aflojen involuntariamente.

-

Aplicaciones comunes:

-

Aeroespacial y aviación: Se utiliza en motores, trenes de aterrizaje y conjuntos críticos en los que la resistencia a las vibraciones es crucial.

-

Automoción y carreras: Asegura componentes de alto rendimiento sometidos a vibraciones extremas.

-

Maquinaria industrial: Evita el aflojamiento en maquinaria pesada y equipos rotativos.

-

Sistemas eléctricos: El cobreado ayuda a la conexión a tierra y a la continuidad eléctrica.

Ventajas:

-

Doble seguridad: Combina bloqueo mecánico (dientes) con cable de seguridad para una retención a prueba de fallos.

-

Resistencia a la corrosión: El cobreado ofrece protección contra la herrumbre y la oxidación.

Normas y especificaciones:

-

Puede cumplir MS, NAS, AN (Normas aeroespaciales) o DIN, ISO (Normas industriales).

-

El material suele incluir acero, acero inoxidable o metales aleados con revestimiento de cobre.

Notas de instalación:

-

Requiere un par de apriete adecuado para que los dientes engranen eficazmente.

- Tuerca dentada cobreada

Este tipo de tuerca es ideal para aplicaciones críticas en las que la resistencia a las vibraciones y el bloqueo secundario (mediante cable de seguridad) son obligatorios para la seguridad y la fiabilidad.

Valoraciones

No hay valoraciones aún.