冷镦加工是一种少切削或无切削的压力加工新工艺

金屬。它是一種利用金屬在下列因素作用下產生塑性變形的加工方法

外力作用下,在模具的幫助下,重新分配和轉移金屬的體積,以形成

所需的零件或坯料。冷镦工艺最适合生产标准的

螺栓、螺絲、螺帽、鉚釘和銷等緊固件

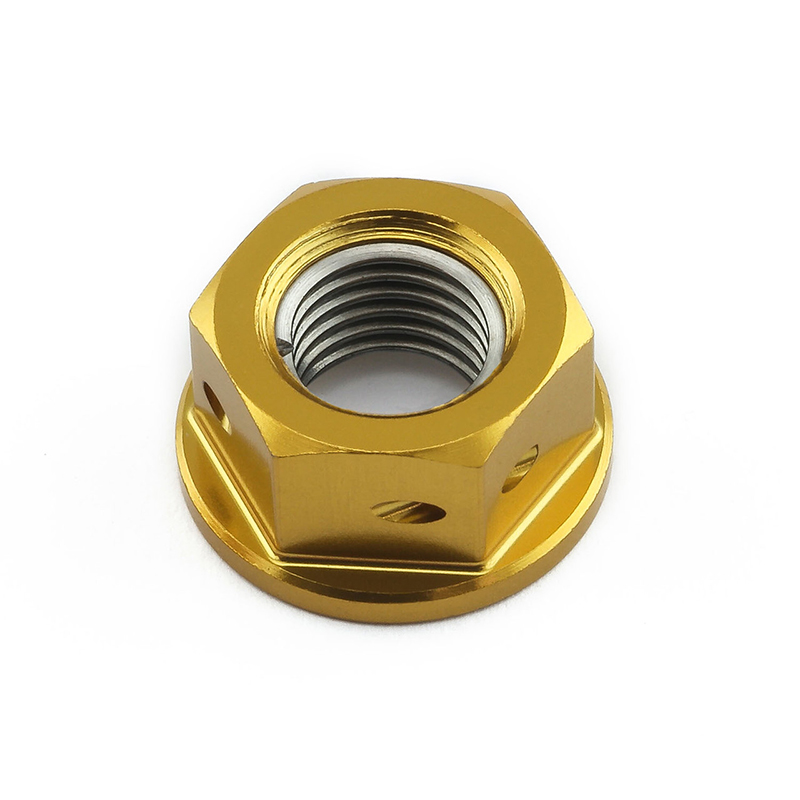

A 安全電線螺帽 氧化鋁黃 是一種專門的電線連接器,專為安全可靠的電氣連接而設計,尤其適用於高溫或惡劣的環境。以下是其主要特性的整體說明:

1.材質與組成

-

機身材質: 通常採用高級 熱固塑料 或 阻燃尼龍 用於耐用性。

-

內部塗層/嵌入: 包含 氧化鋁是一種陶瓷化合物,以其 高熱阻性 和電絕緣特性。

-

顏色: 黃色 (通常表示特定尺寸或溫度等級)。

2.主要功能

-

耐高溫: 的 氧化鋁 此元件可讓線螺帽承受極高的熱度,使其適用於工業、汽車或航太應用。

-

安全連接: 特點 彈簧金屬線圈 (通常由銅或鋼製成),可確保緊密且抗震的連接。

-

阻燃: 外殼材料可防止燃燒和熔化,提高了電氣系統的安全性。

-

耐腐蝕性: 氧化鋁可防止氧化和化學降解。

- 氧化鋁黃

3.應用

-

用於 高溫環境 (如熔爐、引擎、工業機械)。

-

適用於 汽車配線、航太及船舶應用 抗震性極為重要。

-

適用於 鋁銅線連接 (if rated for such use)。

4.安全標準與認證

-

可能符合 UL (Underwriters Laboratories)、CSA 或 IEC 電氣安全標準。

-

額定用於特定 電壓(例如 600V)和溫度範圍 (例如,-40°C 至 +150°C 或更高)。

- 氧化鋁黃

6.優於標準電線螺帽

-

優越 散熱 由於氧化鋁。

-

增強型 機械強度 在高震動環境中。

商品評價

目前沒有評價。