螺栓與螺帽的鎖緊與開口採用非標準設計,搭配

使用非標準工具來解決打開和緊固問題。一般而言,其他

無法插入扳手。在螺母和螺栓的外觀設計中,非標準開槽、

開口或五角、七角、九角或客製化對應槽工具

起到了很好的防盜效果

冷镦加工是一种少切削或无切削的压力加工新工艺

金屬。它是一種利用金屬在下列因素作用下產生塑性變形的加工方法

外力作用下,在模具的幫助下,重新分配和轉移金屬的體積,以形成

所需的零件或坯料。冷镦工艺最适合生产标准的

螺栓、螺絲、螺帽、鉚釘和銷等緊固件

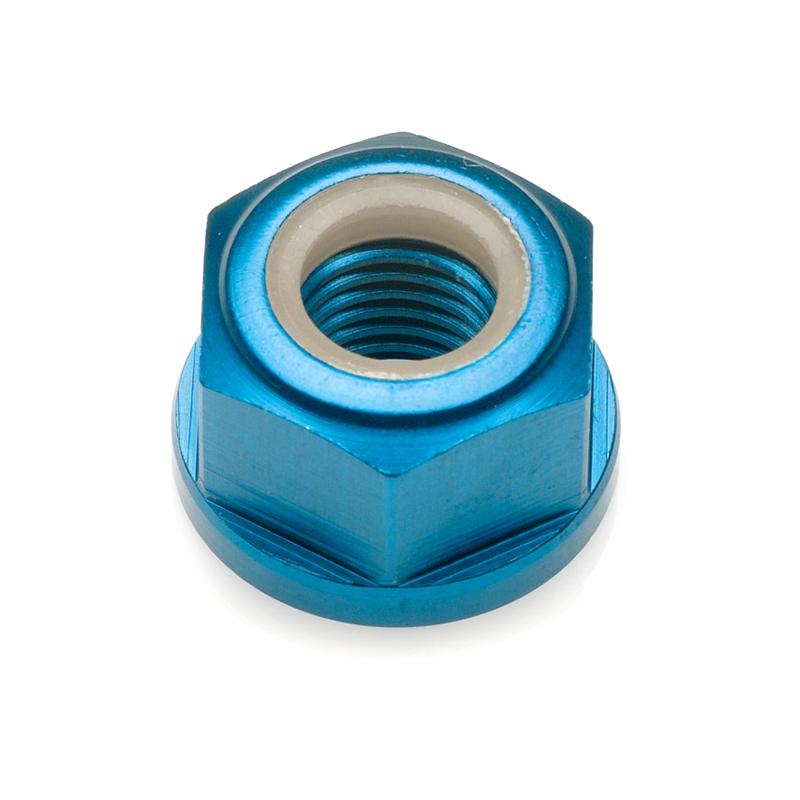

鈦 螺帽金屬鎖緊 是專門設計用來提供高強度、耐腐蝕及安全鎖緊能力的緊固件。這些螺帽常用於對抗震性及耐用性要求極高的航太、汽車、船舶及工業環境。

鈦合金鎖緊螺帽的主要特性:

-

材質組成

-

採用高級鈦合金製成,例如 Ti-6Al-4V(5 級) 或 Ti-6Al-4V ELI (Grade 23).

-

提供極佳的強度重量比、耐腐蝕性和生物相容性。

-

-

鎖定裝置

-

金屬鎖定功能: 通常包括一個不含尼龍的全金屬鎖緊系統(例如:變形螺紋、凸緣設計、或盛行扭力特性),以防止在震動下鬆脫。

-

常見類型:

-

主流扭力鎖緊螺帽 (例如:全金屬硬螺帽)

-

兩件式鎖緊螺帽 (帶有自由旋轉軸環和鎖緊插件)

-

凸緣鋸齒螺帽 (有鋸齒可供握持)

-

-

-

優勢

-

耐高溫: 在極端環境下表現良好(不像尼龍插件,在高溫下會降解)。

-

抗震性: 防止動態應用中的自鬆。

-

輕巧: 是航太及高性能車輛的理想選擇。

-

非磁性、耐腐蝕: 適用於船舶和醫療應用。

-

-

常見應用

-

飛機和太空船組件

-

高性能汽車系統

-

軍事和國防設備

-

化學加工與離岸裝置

-

醫療植入物和裝置 (若使用生物相容性等級製造)

-

-

標準與規格

-

航太: NAS、MS、AN、MIL-SPEC

-

工業級: DIN、ISO、ASTM

-

汽車: 客製化高性能規格

-

與其他鎖緊螺帽比較

-

尼龍插入螺帽 (Nyloc): 更便宜,但在高溫下會降解。

-

不銹鋼鎖緊螺帽: 比鈦重且不耐腐蝕。

-

黃銅或銅鎖緊螺帽: 較軟且不耐用。

總結

鈦螺帽金屬鎖緊是優質的緊固件,適用於對減輕重量、強度和抗震性要求極高的關鍵應用。它們的全金屬鎖緊設計可確保在極端條件下的可靠性,而在這些條件下,塑膠材質的鎖緊機制可能會失效。

商品評價

目前沒有評價。