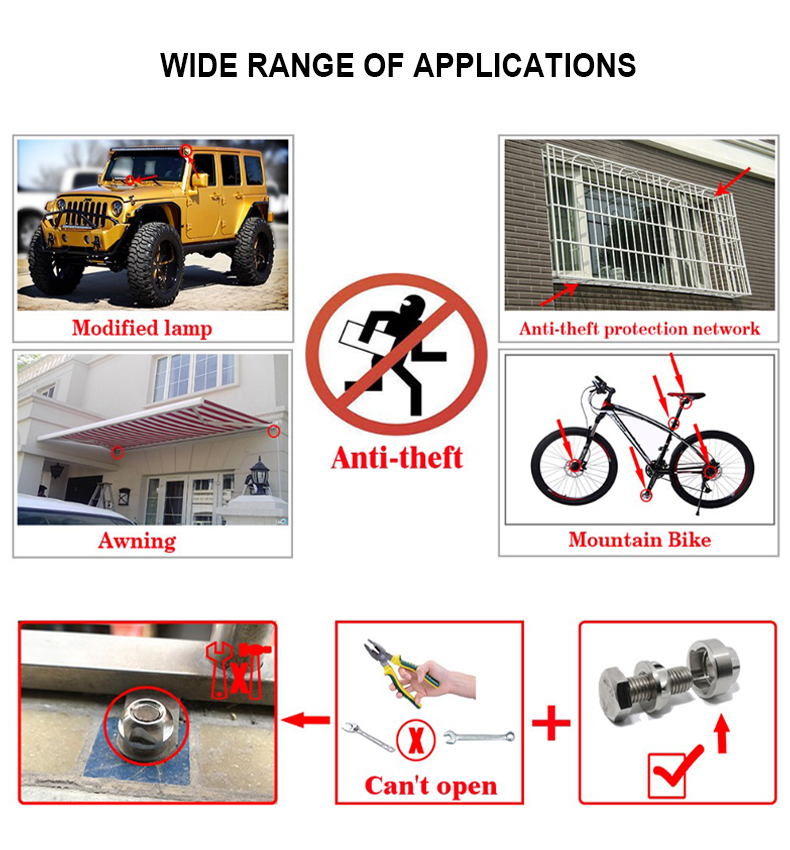

Das Befestigen und Öffnen von Schrauben und Muttern ist nicht standardisiert, und die passende

Zur Lösung der Öffnungs- und Befestigungsprobleme werden nicht genormte Werkzeuge verwendet. Im Allgemeinen werden andere

Schraubenschlüssel können nicht eingesetzt werden. in das Erscheinungsbild Design von Schrauben und Muttern, Nicht-Standard-Schlitzung,

öffnende oder fünfeckige, siebeneckige, neuneckige oder speziell angefertigte entsprechende Nutwerkzeuge

haben eine sehr gute Anti-Diebstahl-Wirkung gespielt

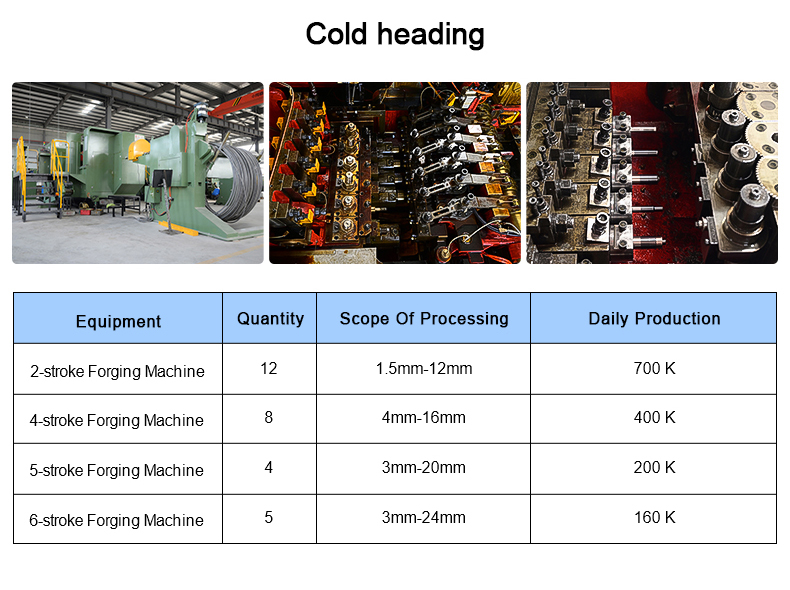

Das Kaltstauchverfahren ist eines der neuen Verfahren für die Druckbearbeitung mit weniger oder gar keiner Zerspanung

Es handelt sich um eine Verarbeitungsmethode, die die plastische Verformung von Metall unter der Einwirkung von

äußere Kräfte, und mit Hilfe von Formen wird das Metallvolumen umverteilt und in die Form gebracht

die gewünschten Teile oder Rohlinge. Das Kaltstauchverfahren ist am besten geeignet für die Herstellung von Standard

Verbindungselemente wie Bolzen, Schrauben, Muttern, Nieten, Stifte usw.

A sperren Nuss ist eine Spezialmutter, die ein Lösen durch Vibrationen, Drehmoment oder andere mechanische Kräfte verhindert, die sonst zum Lösen einer Standardmutter führen könnten. Sie ist eine wichtige Komponente in Branchen und Anwendungen, in denen eine sichere Befestigung unerlässlich ist, insbesondere in Umgebungen mit starken Vibrationen.

Arten von Sicherungsmuttern:

-

Sicherungsmutter mit Nyloneinsatz (Nyloc-Mutter):

- Verfügt über einen Nyloneinsatz, der den Bolzen oder die Schraube festhält, für Reibung sorgt und ein Lösen verhindert.

- Wird häufig in der Automobilindustrie, der Luft- und Raumfahrt und im allgemeinen Maschinenbau eingesetzt.

-

Ganzmetall-Sicherungsmutter:

- Diese vollständig aus Metall gefertigten Sicherungsmuttern nutzen die Verformung des Metalls, um Reibung mit dem Gewinde des Befestigungselements zu erzeugen.

- Sie sind bekannt für ihre Langlebigkeit und ihre Fähigkeit, hohen Temperaturen und rauen Umgebungen zu widerstehen.

-

Gezahnte Flanschsicherungsmutter:

- Verfügt über einen Flansch mit gezackten Kanten, die sich in das Material oder die Oberfläche der Mutter verbeißen, um den Widerstand gegen das Lösen zu erhöhen.

- Wird häufig bei Anwendungen verwendet, bei denen ein höheres Drehmoment erforderlich ist oder wenn das Befestigungselement in weicheren Materialien wie Kunststoff oder Aluminium befestigt werden muss.

-

Vorherrschendes Drehmoment Sicherungsmutter:

- Bei dieser Konstruktion wird durch innere Merkmale (wie z. B. einen gewellten Teil der Mutter) ein konstanter Druck auf die Schraube ausgeübt.

- Wird bei Anwendungen verwendet, bei denen die Mutter sicher sein muss, aber möglicherweise mehrmals angezogen oder eingestellt werden muss, ohne dass das Gewinde beschädigt wird.

Materialien:

- Stahl: Am weitesten verbreitet, bietet Festigkeit und Kosteneffizienz. Kann für Korrosionsbeständigkeit behandelt oder beschichtet werden (z. B. verzinkt).

- Rostfreier Stahl: Für den Einsatz in korrosiven Umgebungen, bietet eine höhere Beständigkeit gegen Rost und Korrosion.

- Messing oder Aluminium: Für Anwendungen, die leichte Materialien mit guter Korrosionsbeständigkeit erfordern.

Anwendungen:

- Automobilindustrie: In Motoren, Aufhängungen und anderen Teilen, die Vibrationen und hohen Drehmomenten ausgesetzt sind, wie z. B. Radmuttern und Antriebswellen.

- Industrielle Ausrüstung: Zur Sicherung von Maschinenteilen, die sich in Bereichen, die ständiger Bewegung und Vibration ausgesetzt sind, nicht lockern können.

- Luft- und Raumfahrt: In Luft- und Raumfahrtkomponenten, um sicherzustellen, dass Befestigungselemente bei hohen Fluggeschwindigkeiten und unter extremen Bedingungen sicher an ihrem Platz bleiben.

- Bauwesen: Für hochbelastete Befestigungen in Bauteilen oder Maschinen, die Vibrationen ausgesetzt sind.

Vorteile:

- Verhindert Lockerung: Bietet eine zuverlässige und sichere Befestigung, die eine versehentliche Demontage aufgrund von Vibrationen oder Bewegungen verhindert.

- Langlebig und stark: Hergestellt aus robusten Materialien, die starken Belastungen, hohen Drehmomenten und Vibrationen standhalten können.

- Wiederverwendbarkeit: Viele Sicherungsmuttern, insbesondere solche mit Nyloneinsatz, können mehrmals wiederverwendet werden, ohne ihre Sicherungsfähigkeit zu verlieren.

- Kosteneffiziente Lösung: Reduziert den Bedarf an teuren, speziellen Schließmechanismen.

- Vielseitigkeit: Erhältlich in verschiedenen Größen, Materialien und Gewindetypen für unterschiedliche Anwendungen und Umgebungen.

Überlegungen:

- Temperatur-Empfindlichkeit: Sicherungsmuttern mit Nyloneinsatz können sich bei sehr hohen Temperaturen (über 250 °C) zersetzen oder ihre Wirksamkeit verlieren, so dass unter extremen Bedingungen Alternativen wie Ganzmetall-Sicherungsmuttern erforderlich sein können.

- Platzbeschränkungen: Einige Sicherungsmuttern, wie z. B. Ganzmetallmuttern, können kompakter sein, während andere, wie z. B. Nyloneinsätze, mehr Platz benötigen.

Bewertungen

Es gibt noch keine Bewertungen.