The fastening and opening of bolts and nuts adopts non-standard design, and the matching

non-standard tools are used to solve the opening and fastening problems. In general, other

wrenches cannot be inserted. In the appearance design of nuts and bolts, non-standard slotting,

opening or pentagonal, heptagonal, nine-corner or custom-made corresponding groove tools

have played a very good anti-theft effect

Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

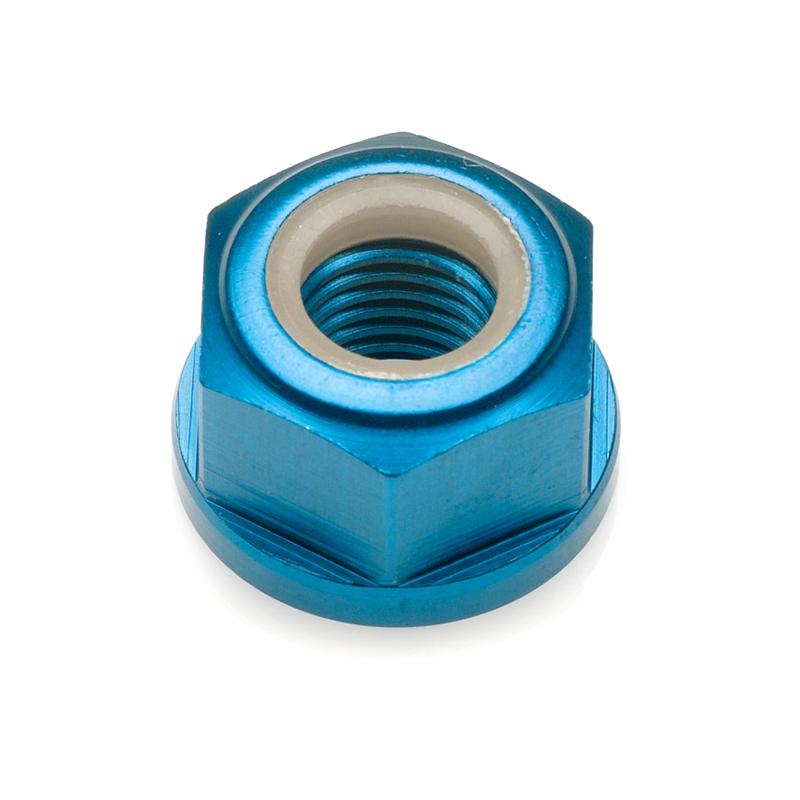

Aluminum Nut with Black Oxide Coating – Detailed Description

An Aluminum nuts black oxide finish is a lightweight, corrosion-resistant fastener designed for applications where weight savings, aesthetics, and moderate environmental protection are important. The black oxide coating provides a dark, matte surface that reduces glare and enhances appearance while offering some functional benefits.

1. Material Composition

-

Base Metal: Aluminum alloy (common grades include 6061-T6, 7075-T6, or 2024-T3).

-

Coating: Black oxide (a chemical conversion coating) formed by reacting aluminum with an oxidizing solution to create a thin, dark layer (Fe₃O₄ in steel, but aluminum black oxide is less common and may involve alternative processes).

2. Key Characteristics

✔ Lightweight – Significantly lighter than steel, ideal for weight-sensitive applications.

✔ Moderate Corrosion Resistance – Better than bare aluminum but less than anodized or plated nuts.

5. Common Applications

-

Automotive & Racing (engine components, body panels).

-

Electronics & Optics (non-reflective, conductive fasteners).

Conclusion

A Aluminum nuts black oxide is an excellent choice for lightweight, non-reflective, and moderately corrosion-resistant fastening needs. It’s widely used in aerospace, automotive, and electronics but may not be suitable for harsh environments without additional protection.

Reviews

There are no reviews yet.