The fastening and opening of bolts and nuts adopts non-standard design, and the matching

non-standard tools are used to solve the opening and fastening problems. In general, other

wrenches cannot be inserted. In the appearance design of nuts and bolts, non-standard slotting,

opening or pentagonal, heptagonal, nine-corner or custom-made corresponding groove tools

have played a very good anti-theft effect

Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

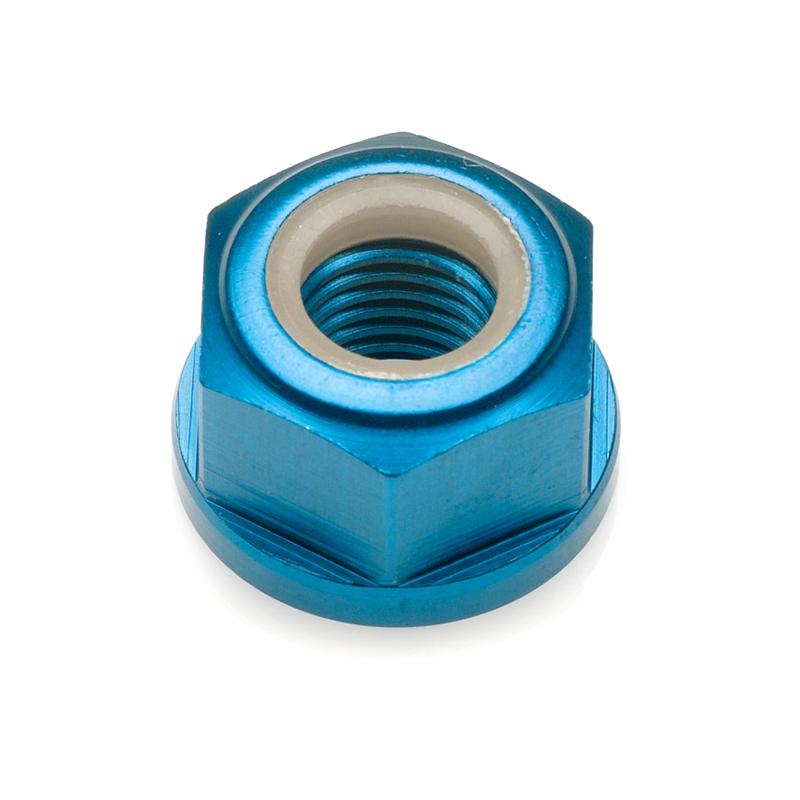

Aluminum Nut with Blue Oxide Coating – Description

Aluminum nuts with a blue oxide coating are lightweight, corrosion-resistant fasteners designed for applications where weight savings and aesthetic appeal are important. The blue oxide finish provides a decorative and mildly protective layer while maintaining the nut’s conductivity and non-magnetic properties.

Key Features:

-

Material:

-

Made from aluminum alloys (typically 6061-T6 or 7075-T6 for higher strength).

-

Lightweight (~1/3 the weight of steel) with good corrosion resistance.

-

-

Blue Oxide Coating:

-

A chemical conversion coating (not anodized) that provides:

-

Mild corrosion resistance (less than anodizing but better than bare aluminum).

-

Decorative blue-black finish (for aesthetic or color-coding purposes).

-

Non-conductive interference (unlike anodizing, which can affect conductivity).

-

-

Thinner than anodizing, so it doesn’t significantly alter thread dimensions.

-

-

Locking Mechanism (If Applicable):

-

Some blue oxide aluminum nuts may include:

-

Nylon insert (Nyloc) for vibration resistance.

-

Serrated flange for better grip.

-

Prevailing torque design (all-metal locking).

-

-

-

Advantages:

-

Lightweight – Ideal for aerospace, automotive, and cycling applications.

-

Non-magnetic & Conductive – Used in electronics and RF applications.

-

Aesthetic appeal – Often used in custom builds, motorcycles, and drones.

-

Moderate corrosion resistance – Suitable for indoor or mild outdoor use.

-

-

Limitations:

-

Not as corrosion-resistant as anodized or stainless steel nuts.

-

Lower strength compared to steel or titanium.

-

Blue oxide can wear off over time with friction.

-

Common Applications:

-

Aerospace & drones (weight-sensitive assemblies).

-

Custom automotive & motorcycles (decorative fasteners).

-

Electronics & electrical enclosures (non-magnetic, conductive properties).

-

Bicycles & sporting equipment (lightweight components).

Conclusion:

Blue oxide aluminum nuts are a good choice for lightweight, non-magnetic applications where moderate corrosion resistance and an attractive finish are desired. However, for harsher environments, anodized or stainless steel nuts may be more suitable.

Reviews

There are no reviews yet.