The fastening and opening of bolts and nuts adopts non-standard design, and the matching

non-standard tools are used to solve the opening and fastening problems. In general, other

wrenches cannot be inserted. In the appearance design of nuts and bolts, non-standard slotting,

opening or pentagonal, heptagonal, nine-corner or custom-made corresponding groove tools

have played a very good anti-theft effect

Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

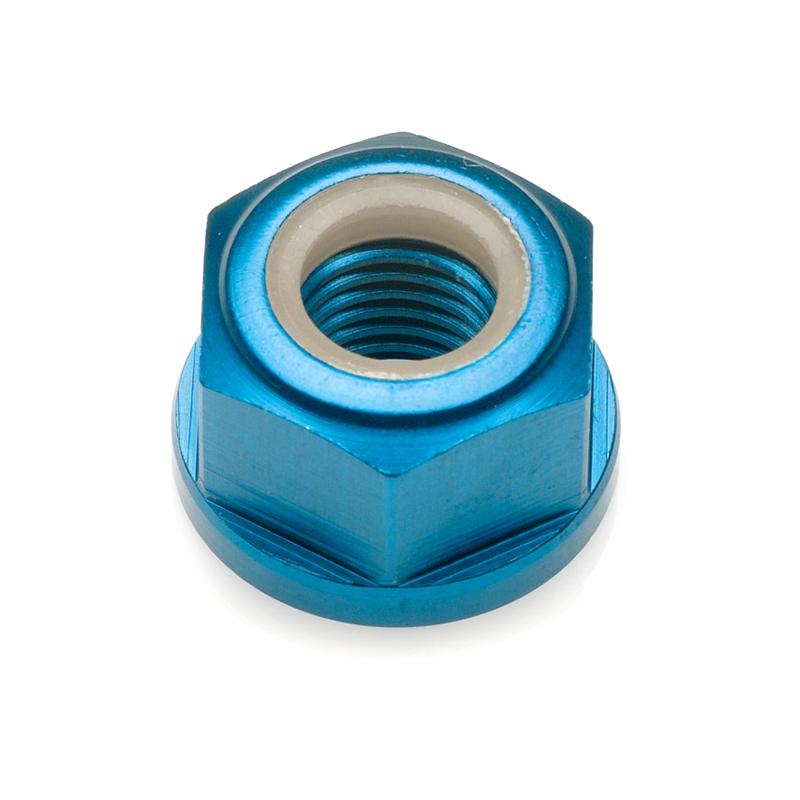

An Aluminum nuts purple oxide is a type of fastener that has undergone a specialized surface treatment to achieve a decorative and corrosion-resistant purple finish. Here’s a detailed description:

1. Material

-

Made from aluminum (typically grades like 6061 or 7075 for a balance of strength and lightweight properties).

2. Purple Oxidation Process

-

The nut undergoes anodizing, an electrochemical process that thickens the natural oxide layer on aluminum.

-

The purple color is achieved through dye infusion during the anodizing process, where the porous oxide layer absorbs a purple dye before sealing.

-

Alternatively, electrolytic coloring (using metallic salts) can produce iridescent or darker purple hues.

3. Features & Benefits

-

Corrosion Resistance – The anodized layer protects against rust and environmental damage.

-

Aesthetic Appeal – Provides a vibrant, consistent purple finish for decorative or color-coding purposes.

-

Durability – Harder surface than raw aluminum, improving wear resistance.

-

Electrical Insulation – Anodized aluminum is non-conductive.

4. Common Applications

-

Aerospace & automotive (lightweight, corrosion-resistant fasteners).

-

Electronics & machinery (color-coded components).

-

Aluminum nuts purple oxide

-

Marine & outdoor equipment (enhanced weather resistance).

5. Variations

-

Bright Purple – Vivid, dye-based anodizing.

-

Iridescent Purple – Created via interference effects in hard anodizing.

-

Matte or Gloss Finish – Depending on pre-treatment (e.g., bead blasting for matte).

6. Limitations

-

Not as strong as steel nuts for high-torque applications.

-

The color may fade under prolonged UV exposure unless specially sealed.

Reviews

There are no reviews yet.