The fastening and opening of bolts and nuts adopts non-standard design, and the matching

non-standard tools are used to solve the opening and fastening problems. In general, other

wrenches cannot be inserted. In the appearance design of nuts and bolts, non-standard slotting,

opening or pentagonal, heptagonal, nine-corner or custom-made corresponding groove tools

have played a very good anti-theft effect

Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

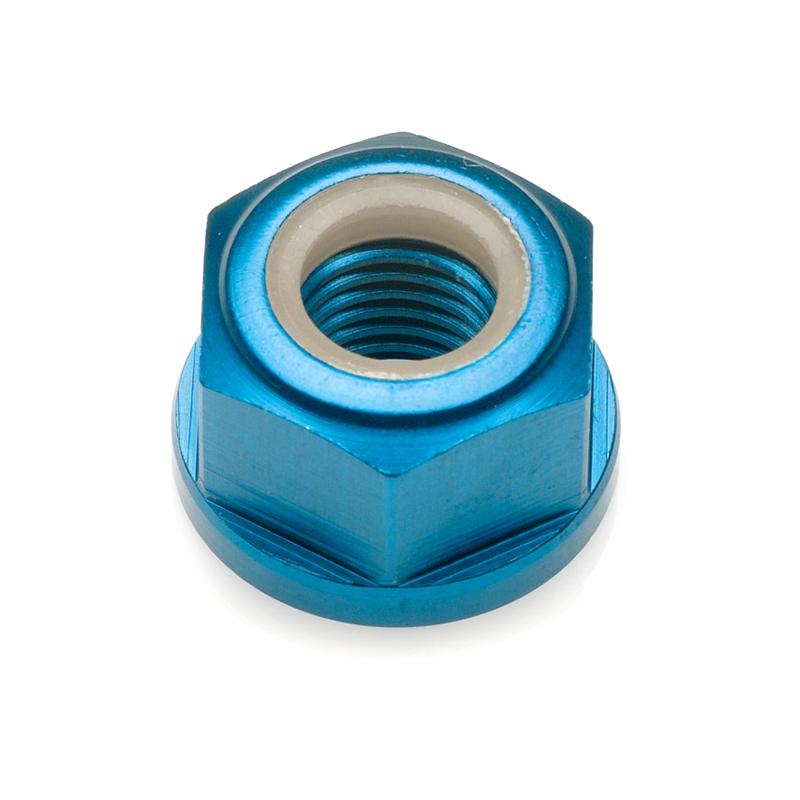

An Aluminum nuts red oxide is a fastener that has undergone a surface treatment to achieve a red-colored finish, typically through anodizing, chemical dyeing, or specialized oxide coatings. This process enhances both aesthetics and functionality. Below is a detailed breakdown:

1. Material

-

Made from aluminum alloys (common grades: 6061-T6, 2024, or 7075 for strength and corrosion resistance).

2. Red Oxide Process

Anodized Red

-

Sulfuric Acid Anodizing (Type II) – The aluminum nut is anodized to create a porous oxide layer, then dyed red using organic or inorganic dyes before sealing.

-

Hard Anodizing (Type III) – Produces a thicker, more durable layer, sometimes resulting in a deeper red or burgundy hue.

Red Chromate Conversion Coating

-

A chemical treatment (e.g., Alodine/MIL-DTL-5541) that deposits a reddish-gold or red oxide layer.

-

Provides corrosion resistance while maintaining electrical conductivity.

Specialized Red Oxide Coatings

-

Some manufacturers apply ceramic-based or epoxy-infused red coatings for extreme environments.

3. Features & Benefits

-

Corrosion Resistance – Protects against oxidation, salt spray, and chemicals.

-

High Visibility – Red color is useful for safety markings or assembly identification.

-

Decorative Appeal – Used in consumer products, automotive, and custom builds.

-

Lightweight – Maintains aluminum’s strength-to-weight ratio.

4. Common Applications

-

Aerospace & Defense – Red anodized nuts for high-visibility or critical assemblies.

-

Automotive & Racing – Custom red fasteners for engine bays or suspension parts.

-

Electronics – Color-coded nuts in circuit boards or machinery.

-

Marine & Outdoor Gear – Enhanced weather resistance with a bold appearance.

5. Variations in Red Finish

-

Bright Red – Achieved with organic dyes in anodizing (common for decorative uses).

-

Dark Red/Burgundy – Result of longer dye immersion or hard anodizing.

-

Matte or Glossy – Depends on surface prep (e.g., bead blasting for matte, polishing for gloss).

6. Limitations

-

UV Sensitivity – Red dyes may fade over time if not properly sealed.

-

Lower Strength – Aluminum nuts are not suitable for high-torque applications like steel.

-

Chemical Restrictions – Some red chromates contain regulated substances (e.g., hexavalent chromium).

Industry Standards

-

Anodizing: MIL-A-8625 (Type II/III)

-

Chromate Coating: MIL-DTL-5541 (Class 1A for hexavalent chromium, Class 3 for RoHS-compliant alternatives)

Reviews

There are no reviews yet.