The fastening and opening of bolts and nuts adopts non-standard design, and the matching

non-standard tools are used to solve the opening and fastening problems. In general, other

wrenches cannot be inserted. In the appearance design of nuts and bolts, non-standard slotting,

opening or pentagonal, heptagonal, nine-corner or custom-made corresponding groove tools

have played a very good anti-theft effect

Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

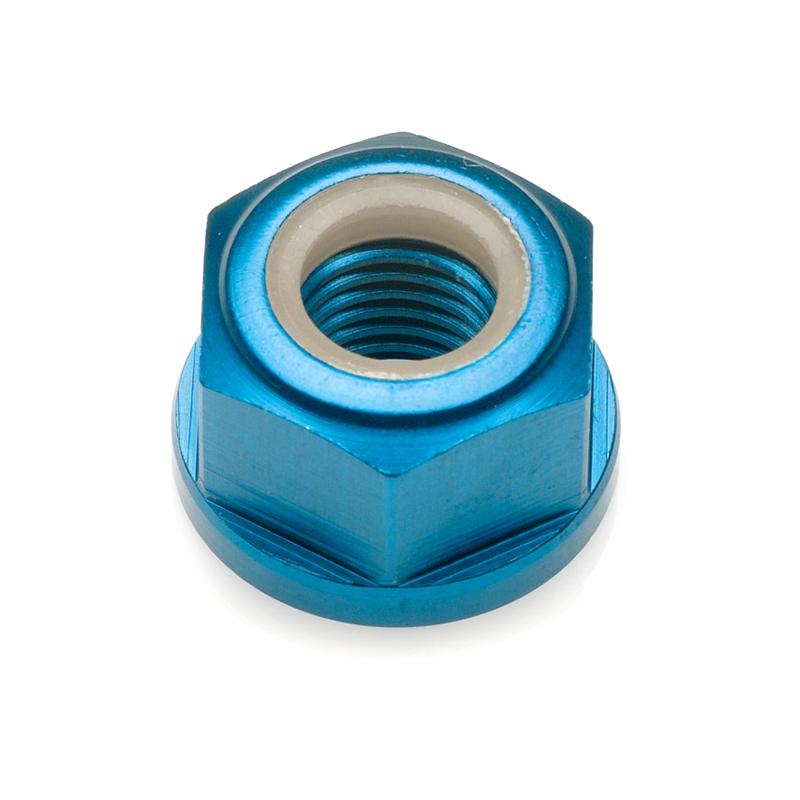

Aluminum Alloy Nylon Lock Nut – Detailed Description

An aluminum alloy nylon lock nut is a lightweight, vibration-resistant fastener that combines the strength and corrosion resistance of aluminum with the locking capability of a nylon insert. These nuts are commonly used in applications where weight savings, resistance to loosening, and moderate environmental protection are required.

1. Material Composition

Base Material:

-

Aluminum Alloy (typically 6061-T6 or 7075-T6)

-

6061-T6: Good strength, corrosion resistance, and weldability (general-purpose use).

-

7075-T6: Higher strength (near steel levels) but less corrosion-resistant (used in aerospace/military).

-

Locking Mechanism:

-

Nylon Insert (PA66 or equivalent) – A nylon ring embedded at the top of the nut that creates friction against the bolt threads, preventing loosening from vibration.

-

Temperature resistance: -40°C to +120°C (-40°F to +250°F) (may degrade at higher temps).

-

Chemically resistant to oils, fuels, and solvents (but not strong acids/bases).

-

2. Key Features & Benefits

✔ Lightweight – Up to 65% lighter than steel nuts, ideal for aerospace, automotive, and electronics.

✔ Reusable (to a degree) – Can be reused a few times before the nylon wears out.

7. Installation & Maintenance Tips

-

Use with Anti-Seize – Prevents galling in aluminum threads.

-

Avoid Over-Tightening – Can strip aluminum threads or crush the nylon insert.

-

Check Nylon Condition – If the insert is cracked or loose, replace the nut.

-

For High-Temp Use – Consider all-metal lock nuts (e.g., aluminum with a deformed thread).

Conclusion

An aluminum alloy nylon lock nut is an excellent choice for lightweight, vibration-resistant applications where corrosion resistance is needed. While not as strong as steel, it provides a reliable locking mechanism for moderate-load environments.

Reviews

There are no reviews yet.