The fastening and opening of bolts and nuts adopts non-standard design, and the matching

non-standard tools are used to solve the opening and fastening problems. In general, other

wrenches cannot be inserted. In the appearance design of nuts and bolts, non-standard slotting,

opening or pentagonal, heptagonal, nine-corner or custom-made corresponding groove tools

have played a very good anti-theft effect

Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

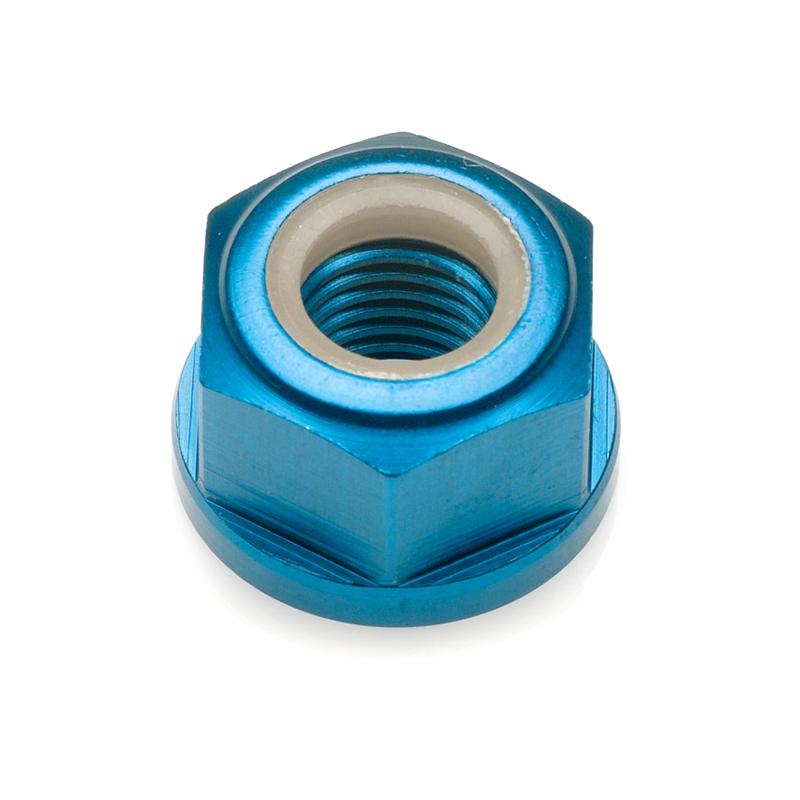

Hexagon flange metal lock nuts are specialized fasteners designed to provide a secure, vibration-resistant connection in mechanical assemblies. Here’s a detailed description:

Key Features:

-

Hexagonal Head – Features a six-sided (hex) head for easy tightening/loosening with standard wrenches or sockets.

-

Integrated Flange – The built-in flange distributes clamping pressure over a wider surface area, reducing the risk of damage to the connected material and improving joint stability.

-

Locking Mechanism – Typically includes a nylon insert (metal insert or deformed threads) that creates friction against the bolt, preventing loosening due to vibrations or dynamic loads. Hexagon flange metal lock nut

-

Material – Commonly made from steel (carbon or stainless), brass, or other metals, often with corrosion-resistant coatings like zinc plating or black oxide.

-

Thread Type – Available in metric (M) or imperial (UNC/UNF) thread sizes to match corresponding bolts/screws.

Advantages:

-

Vibration Resistance – Ideal for automotive, machinery, and aerospace applications where movement could loosen standard nuts.

-

Eliminates Need for Washers – The flange acts as a built-in washer, simplifying assembly.

-

Stronger Grip – The locking feature ensures long-term fastener integrity.

- Hexagon flange metal lock nut

Common Applications:

-

Automotive components (engine parts, suspension systems)

-

Industrial machinery

-

Electrical enclosures

-

Construction and structural assemblies

Variants:

-

Nylon Insert Lock Nuts – Have a polymer ring for elasticity and grip.

-

All-Metal Lock Nuts – Use deformed threads or slots for a metal-to-metal locking action.

-

Serrated Flange Nuts – Feature teeth under the flange to bite into surfaces for added resistance.

Reviews

There are no reviews yet.