The fastening and opening of bolts and nuts adopts non-standard design, and the matching

non-standard tools are used to solve the opening and fastening problems. In general, other

wrenches cannot be inserted. In the appearance design of nuts and bolts, non-standard slotting,

opening or pentagonal, heptagonal, nine-corner or custom-made corresponding groove tools

have played a very good anti-theft effect

Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

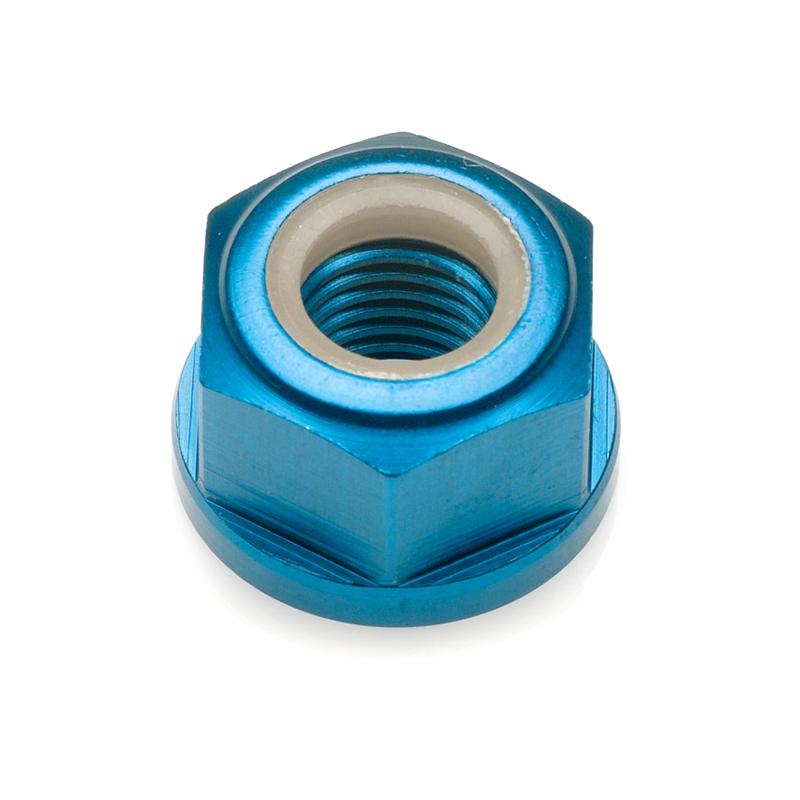

Titanium nut metal locking features are specialized fasteners designed to provide high strength, corrosion resistance, and secure locking capabilities in demanding applications. These nuts are commonly used in aerospace, automotive, marine, and industrial settings where vibration resistance and durability are critical.

Key Features of Titanium Alloy Locking Nuts:

-

Material Composition

-

Made from high-grade titanium alloys such as Ti-6Al-4V (Grade 5) or Ti-6Al-4V ELI (Grade 23).

-

Offers an excellent strength-to-weight ratio, corrosion resistance, and biocompatibility.

-

-

Locking Mechanism

-

Metal Locking Feature: Typically includes a nylon-free, all-metal locking system (e.g., deformed threads, flanged design, or a prevailing torque feature) to prevent loosening under vibration.

-

Common Types:

-

Prevailing Torque Lock Nuts (e.g., all-metal stiff nuts)

-

Two-Piece Lock Nuts (with a free-spinning collar and locking insert)

-

Flanged Serrated Nuts (with serrations for grip)

-

-

-

Advantages

-

High Temperature Resistance: Performs well in extreme environments (unlike nylon inserts, which degrade at high temps).

-

Vibration Resistance: Prevents self-loosening in dynamic applications.

-

Lightweight: Ideal for aerospace and performance vehicles.

-

Non-Magnetic & Corrosion-Resistant: Suitable for marine and medical applications.

-

-

Common Applications

-

Aircraft and spacecraft components

-

High-performance automotive systems

-

Military and defense equipment

-

Chemical processing and offshore installations

-

Medical implants and devices (if made from biocompatible grades)

-

-

Standards & Specifications

-

Aerospace: NAS, MS, AN, MIL-SPEC

-

Industrial: DIN, ISO, ASTM

-

Automotive: Custom high-performance specs

-

Comparison with Other Locking Nuts

-

Nylon Insert Nuts (Nyloc): Cheaper but degrade at high temps.

-

Stainless Steel Lock Nuts: Heavier and less corrosion-resistant than titanium.

-

Brass or Copper Lock Nuts: Softer and less durable.

Conclusion

Titanium nut metal locking are premium fasteners for critical applications where weight savings, strength, and vibration resistance are essential. Their all-metal locking design ensures reliability in extreme conditions where plastic-based locking mechanisms would fail.

Reviews

There are no reviews yet.