The fastening and opening of bolts and nuts adopts non-standard design, and the matching

non-standard tools are used to solve the opening and fastening problems. In general, other

wrenches cannot be inserted. In the appearance design of nuts and bolts, non-standard slotting,

opening or pentagonal, heptagonal, nine-corner or custom-made corresponding groove tools

have played a very good anti-theft effect

Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

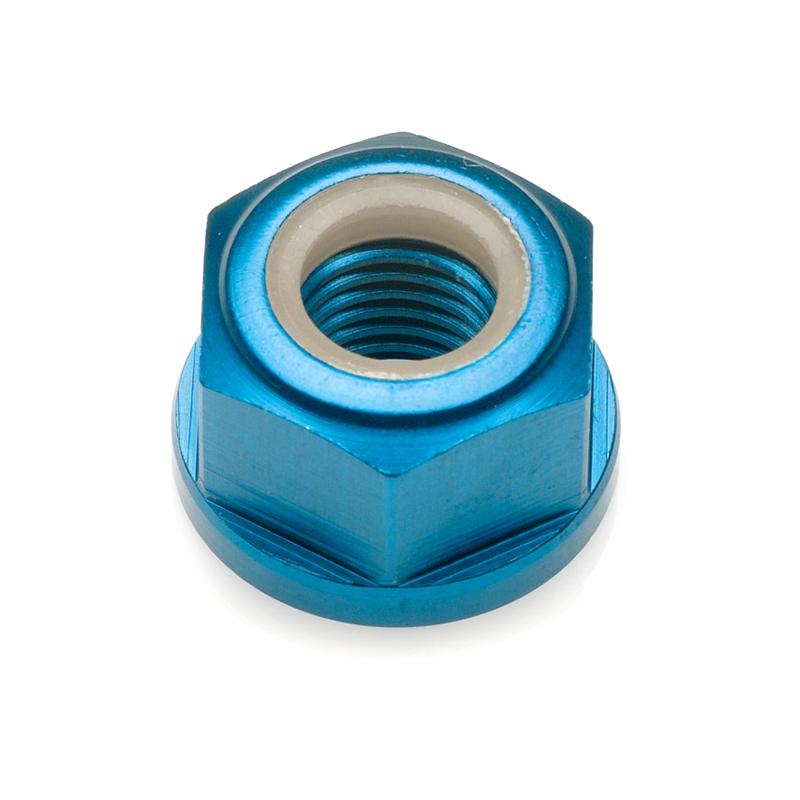

A Titanium nut purple electroplating is a high-performance fastener that combines the lightweight strength of titanium with an aesthetically striking purple surface finish. Here’s a detailed description:

Material: Titanium Alloy

-

Typically made from Grade 5 (Ti-6Al-4V) or similar aerospace-grade titanium.

-

Offers high strength-to-weight ratio, corrosion resistance, and durability.

-

Suitable for extreme environments, including aerospace, automotive, and marine applications.

Plating/Coating: Purple Finish

-

Achieved through anodization, a controlled electrochemical process that creates an oxide layer.

-

The purple hue is produced by adjusting voltage during anodizing, resulting in a vibrant, wear-resistant color.

-

Enhances aesthetics while maintaining corrosion resistance.

- Titanium nut purple electroplating

Features:

-

Lightweight – Significantly lighter than steel nuts.

-

High Strength – Comparable to many steel fasteners but with better fatigue resistance.

-

Non-Magnetic & Biocompatible – Ideal for medical and electronics applications.

-

Decorative & Customizable – The purple finish adds a unique, premium look for high-end or custom builds.

Common Applications:

-

Aerospace & Racing – Where weight savings and strength are critical.

-

Bicycles & Motorcycles – Custom builds and performance upgrades.

-

Medical Devices – Due to titanium’s biocompatibility.

-

Luxury & Consumer Electronics – For aesthetic and functional appeal.

This nut combines functionality, durability, and style, making it a popular choice in both industrial and decorative applications.

Reviews

There are no reviews yet.