Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

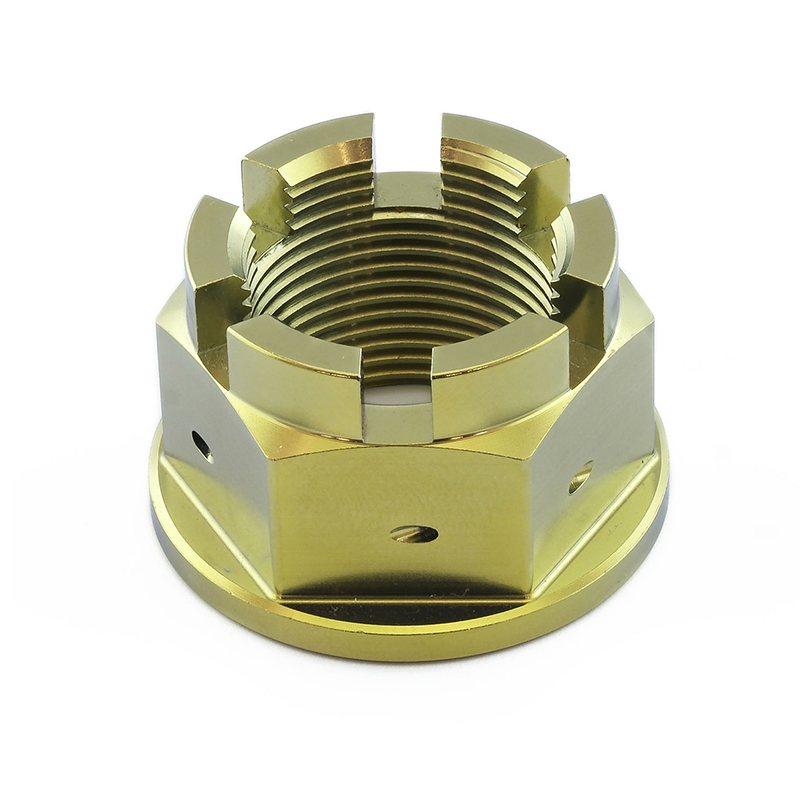

A safety wire copper-plated tooth nut is a specialized fastener designed for applications requiring secure locking to prevent loosening under vibration or dynamic loads. Below is an overall description of its key features and uses:

Key Features:

-

Copper-Plated Finish

-

Provides corrosion resistance and enhances conductivity, making it suitable for electrical grounding or EMI/RFI shielding applications.

-

Improves durability in harsh environments (e.g., aerospace, automotive, or marine industries).

-

-

Tooth Design (Serrated Flange or Teeth Under the Nut)

-

The nut has serrations (teeth) on the bearing surface that bite into the mating material, increasing resistance to rotation.

-

Ensures a tight, vibration-resistant lock without needing additional washers.

- Toothed nut copper plated

-

-

Safety Wire Holes

-

Pre-drilled holes allow the nut to be secured with safety wire (locking wire), commonly used in aviation, motorsports, and military applications.

-

The wire is threaded through adjacent fasteners to prevent unintentional loosening.

-

Common Applications:

-

Aerospace & Aviation: Used in engines, landing gear, and critical assemblies where vibration resistance is crucial.

-

Automotive & Racing: Secures high-performance components subjected to extreme vibrations.

-

Industrial Machinery: Prevents loosening in heavy machinery and rotating equipment.

-

Electrical Systems: Copper plating aids in grounding and electrical continuity.

Advantages:

-

Double Security: Combines mechanical locking (teeth) with safety wire for fail-safe retention.

-

Corrosion Resistance: Copper plating offers protection against rust and oxidation.

Standards & Specifications:

-

May comply with MS, NAS, AN (Aerospace Standards) or DIN, ISO (Industrial Standards).

-

Material typically includes steel, stainless steel, or alloy metals with copper plating.

Installation Notes:

-

Requires proper torque to ensure teeth engage effectively.

- Toothed nut copper plated

This type of nut is ideal for critical applications where vibration resistance and secondary locking (via safety wire) are mandatory for safety and reliability.

Reviews

There are no reviews yet.