Cold heading process is one of the new processes for pressure machining of less or no cutting

metal. It is a processing method that utilizes the plastic deformation of metal under the action of

external forces, and with the aid of molds, redistributes and transfers the volume of metal to form

the required parts or blanks. The cold heading process is most suitable for producing standard

fasteners such as bolts, screws, nuts, rivets, and pins.etc

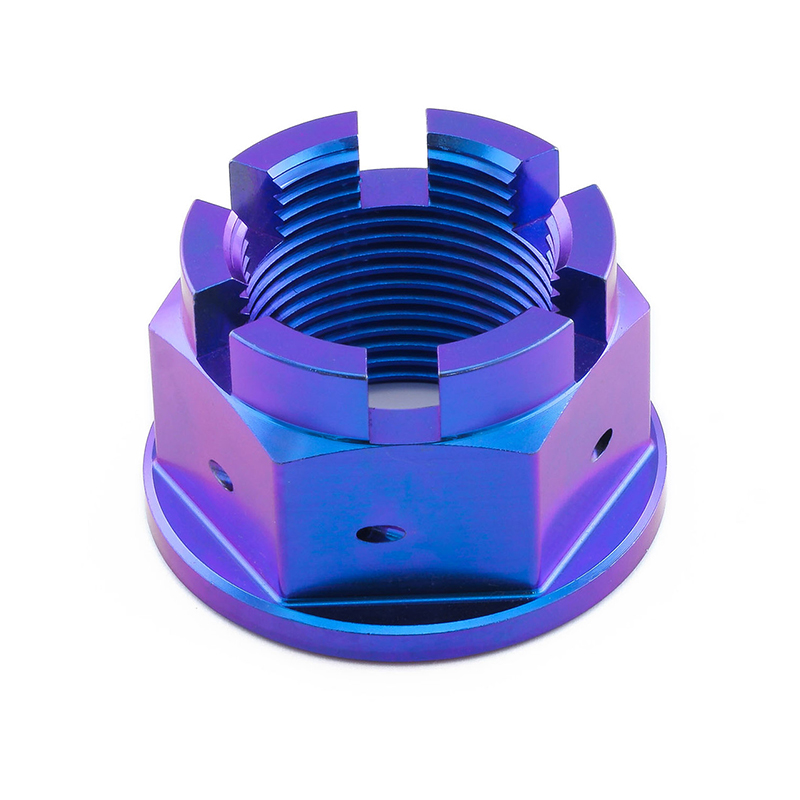

The safety line purple plated tooth nut is a specialized fastener designed for applications where visibility, corrosion resistance, and secure locking are essential. Here’s an overall description of its key features:

1. Purple Plating

-

The nut features a distinctive purple electroplated finish, which provides:

-

Corrosion Resistance: Protects against rust and environmental degradation.

-

High Visibility: The purple color helps in quick identification and inspection, useful in safety-critical applications.

-

Aesthetic Appeal: Often used in industries where color-coding is important.

- Toothed nut purple plated

-

2. Tooth Design (Serrated Flange or Teeth)

-

The nut has integrated teeth or serrations on the bearing surface (usually under the head or flange) that:

-

Prevent Loosening: The teeth bite into the mating surface, resisting vibration and torque.

-

Eliminate the Need for Washers: The serrations act as a built-in locking mechanism.

-

3. Safety Line Feature

-

Some versions may include a safety line or marking (e.g., a colored stripe) to indicate proper torque or detect loosening over time.

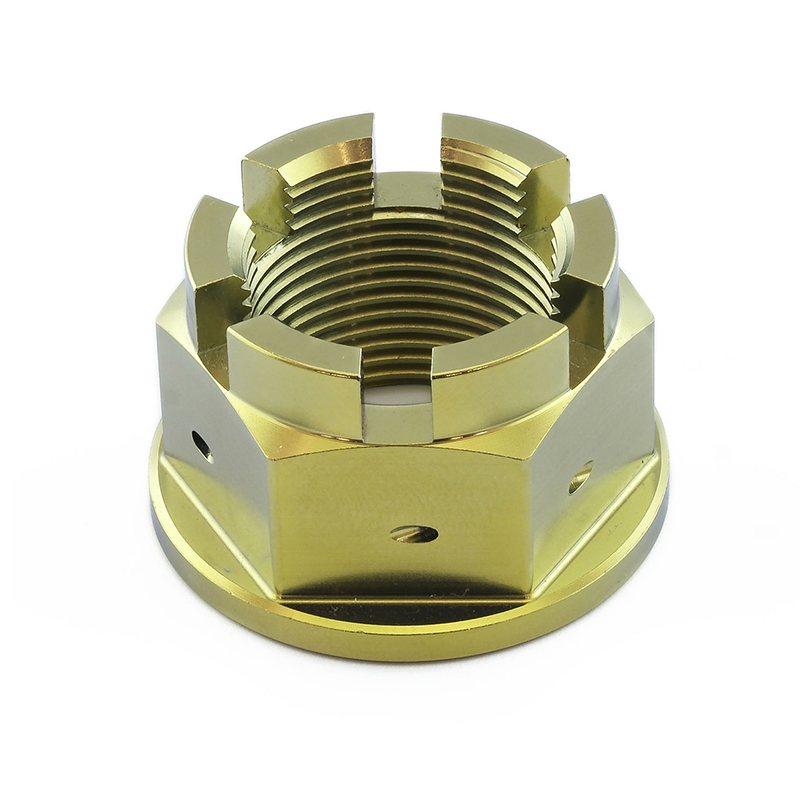

4. Material & Strength

-

Typically made from carbon steel, alloy steel, or stainless steel.

-

May meet industry standards like DIN, ISO, or ANSI for mechanical properties (e.g., Grade 8, Class 10).

- Toothed nut purple plated

5. Common Applications

-

Automotive & Aerospace: High-vibration environments.

-

Railway & Heavy Machinery: Secure fastening under dynamic loads.

-

Electrical & Telecom: Color-coded for safety checks.

-

Construction & Infrastructure: Corrosion-resistant outdoor use.

6. Standards & Compliance

-

May conform to DIN 6923 (flange serrated nuts), ISO 7040, or other industry-specific certifications.

This nut is ideal for industries requiring high-security fastening with visual indicators for safety compliance. Would you like details on a specific standard or application?

Reviews

There are no reviews yet.